The synchros were very tight initially, loosened some in 1st 100 miles. About 50 miles in, I started making a point of downshifting into 3rd, 2nd, 1st to break in synchros. The transmission has a bit of whine in all gears, I will monitor closely for any change. As mentioned on my Drivetrain Reassembly Page, I had made up a pair of gauges to monitor torque tube bearing position. The following three pictures illustrate the gauges used and the initial measurements. The actual measurements as absolute values are really meaningless since I am only checking for differences over time. The pics below are mostly to refresh my memory when checking periodically, and to show others who may be curious about my methods how I went about it.

Initially the torque tube bearings were almost completely silent. With a stethoscope I was able to detect that there were bearings in the tube, but they could not be heard without the stethoscope.

The transaxle makes just enough noise that I can tell whether it is spinning or not in neutral when engaging/disengaging the clutch. If I have the HVAC fan on any but the lowest position or the radio on I can't hear the transaxle.

The clutch has a very minor shudder first thing in the morning just backing out of the garage, down the driveway and into first gear, or the first engagement at the parking garage when leaving work. Aside from that it takes up smoothly and firmly.

No new rattles or squeaks, though many noises have disappeared. Additionally, there had been a mystery rattle for a while, a high-pitched, ringing rattling sound at low RPM. I believe that the high-pitched ringing may have been the races in the TT bearings, and I have localized the rattling to the catalytic converter. It appears to be the core rattling after the casing heats up and expands. It did not rattle while I had it out, when it was cold and I shook it around.

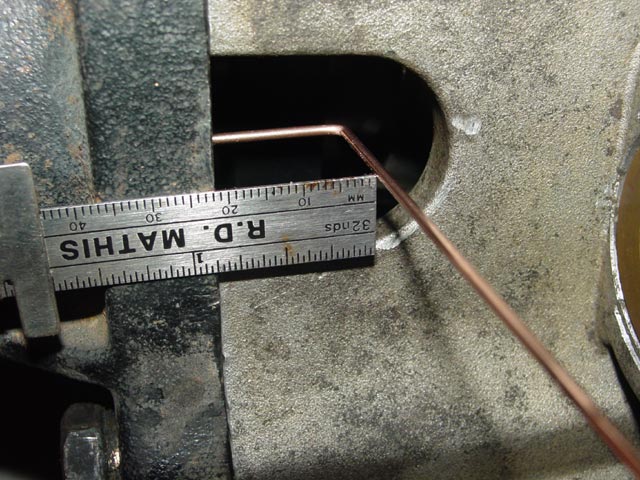

Before installing the front heat shield, I made a gauge out of welding rod to check the front carrier location. I made the gauge in such a way that this check could be performed with the heat shield and cat in place. Here is the initial measurement recorded for posterity.

Here is a similar measurement of the rear carrier.

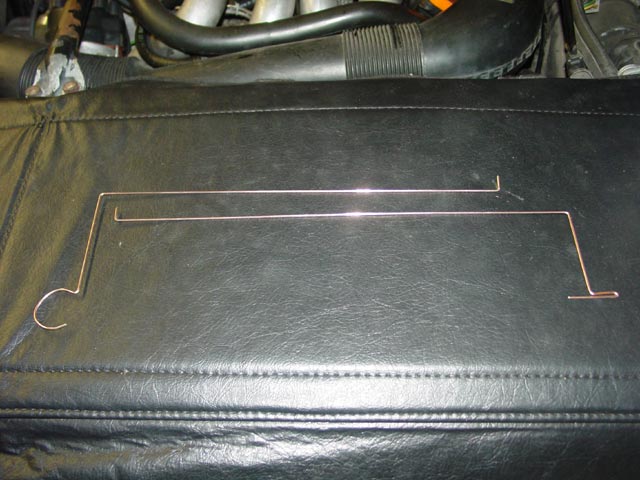

These are the gauges I made up for checking carrier position. The front one has a "C" formed in it to indicate "Clutch End" and the rear one has a "T" formed in it to indicate "Transaxle End". The gauges themselves and their exact dimensions would not be of use on any other car, but the concept may be of general interest. This is the method I will be using in the future to check the bearing carrier position over time.

99,347 - 170 Miles: Re-checked for front and rear carrier walk using above method. No movement detected.

99,383 - 206 Miles: Still stiff shifting in the first 1/4-1/2 mile in the morning, Really smoothing out when warm with 2nd still pretty tight and 1st maybe 1/2 way broken in. Able to upshift and downshift to/from gears as appropriate for speed without grinding.

99,837 - 660 Miles: Checked while servicing Clutch Hydraulics. No movement of TT bearing carriers. Shifting is becoming much more manageable, with an occasional struggle to get into 1st when cold but otherwise working very well. Note that the fresh Clutch hydraulics have made the clutch noticeably smoother, more linear and predictable. I'm confident that the hose accounts for most of the improvement.

100,187 - 1,010 Miles: Checked toward end of Christmas break(Around Jan 4, 2009). No movement of TT bearing carriers. Shifting is about the same. However, most of the miles I've put on since the last update have been highway miles. I'm still exercising the 1st & 2nd synchros as much as I can though. 3rd seems to be fine, not needing any special attention. And, it seems that the gear whine may be abating a bit. Maybe it just needed to wear in a bit, the gears are probably finding a new wear pattern with the new bearings.