Tom Tweed's Boatbuilding Pages

Page 10- Launching

I made arrangements with a trucking company and Driscoll's boat yard in San Diego Bay to have the boat brought down and dropped in the water. I made a temporary crutch to hold the mast horizontally by lashing it to the gallows frame in the rear for the short trip to the boatyard. Then I watched in amazement as a single truck driver arrived at Hog Fish Studios and loaded the boat onto the special-purpose trailer by himself in about an hour. An hour later we pulled into Driscoll's yard, after quite a gawker-filled drive over surface streets to the bay.

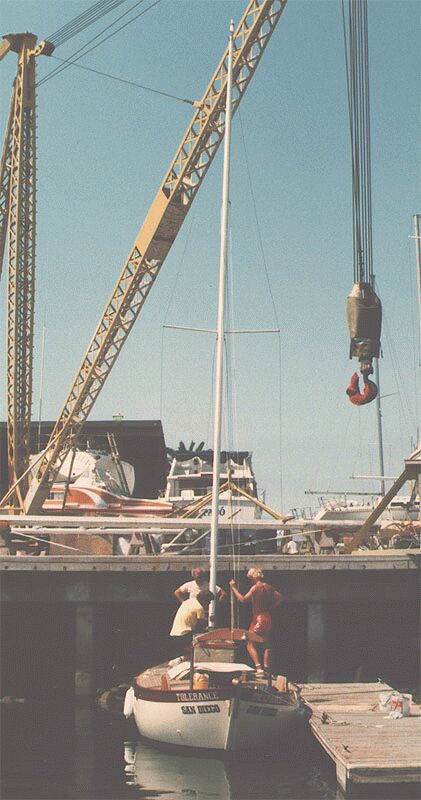

Hog Fish had hand lettered the name of the boat and hailing port on the stern for me as a parting gift. While I had toyed with the idea of naming the boat "Da Kine" at one point (Hawaiian slang for "The Best"), the proper and perfect name for it came to me in an epiphany one day. "Tolerance" stood for an ideal that I believed the world could use more of in human affairs, and it also was a virtue my long-suffering wife had to possess in spades, as I spent every free hour and dollar on this project for those last five years. She didn't share my enthusiasm for offshore sailing, and didn't quite understand why we possessed a sailing yacht when we didn't even own a home yet! She was quite convinced, at times ,that I was going to get on the boat, sail off into the sunset without her, and never be seen again.

Finally, there was an aspect to the name that referred to the level of accuracy to which my carpentry skills were required to be raised in order to complete this project. As a "rig-axe framer" in the custom residential field, I was used to working to tolerances of about 3/8" in plumb and square. For this job, I not only had to learn to deal with compound curves, which were never present in the homes I built, but I had to conform to tolerances of an 1/8 inch or less. The experience developed my skills to the point where I "graduated" to being a finish carpenter from a framer- it was quite an apprenticeship. As a matter of fact, when Gerry Driscoll, the owner of the yard and a world-renowned sailor and boatbuilder himself, with much America's Cup experience, inspected my boat that day and learned that I had built it myself, he offered me a job as a boatwright in his shop on the spot.

Maryann christened the boat with the traditional champagne bottle as it was lifted in the slings,

hoisted over the seawall, and dropped in the water.

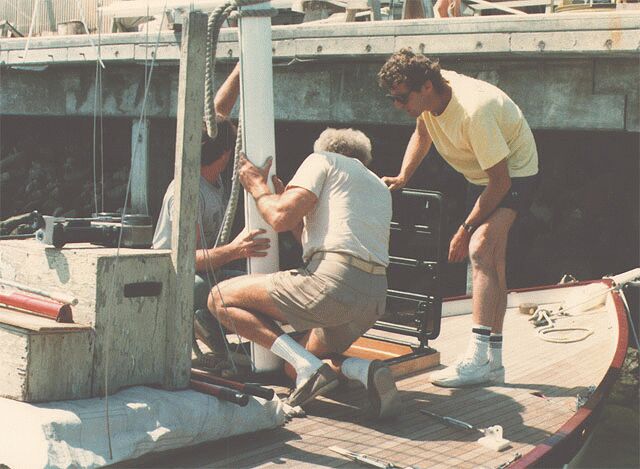

The crane then lifted the mast and we manuvered it through the deck collar and down to the mast step, fitting it on the keel below. The shrouds and stays were already rigged to the mast, and we had the turnbuckles attached to the chainplates on the boat. All that needed to be done was to cut the 3/16" SS wire to length and swage on the terminal fittings, then tighten and attach everything. There was only one hitch in the plans, as it turned out that the mast rake was too great for the straight speaders we had installed on the mast. The upper shroud had a dog-leg in it. I had to correct this over the next couple of weeks by fabricating an angled attachment piece to sweep back the spreaders by about 30 degrees, and then go aloft in a bosun's chair and install it.

Otherwise, the rig was solid and in good enough shape to motor the boat around. At this point I was so broke anyway that I had not even bought the sails yet, so the spreader problem didn't matter- the boat couldn't be sailed yet anyway. What was important was that she floated right on her lines, and after tightening up the packing gland on the shaft log, didn't leak a drop!

After finishing up the rigging at Driscoll's dock, we fired up the motor for the first time and brought the boat over to the slip I had rented at Shelter Cove, and it was party time! This was one of the most satisfying sundowners of my entire life to that point.

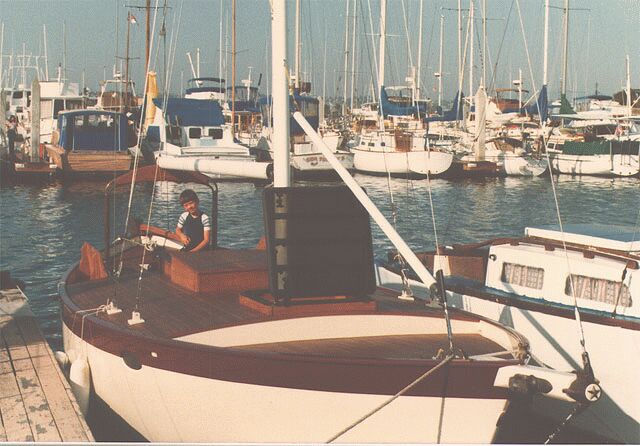

My little brother Kevin lingering at the helm. Today, he is a tugboat captain on San Francisco Bay, and quite a boatman in his own right.

To the NEXT PAGE

Back to HOME