A surprising number of different testers were developed for the D-Jetronic system. I've made a hobby of collecting these testers and learning about what they can do. Note - I'm not in the business of renting them out. Pelican Parts has an excellent rental service with two of the most capable testers, the Bosch and VW testers.

(*) testers I own

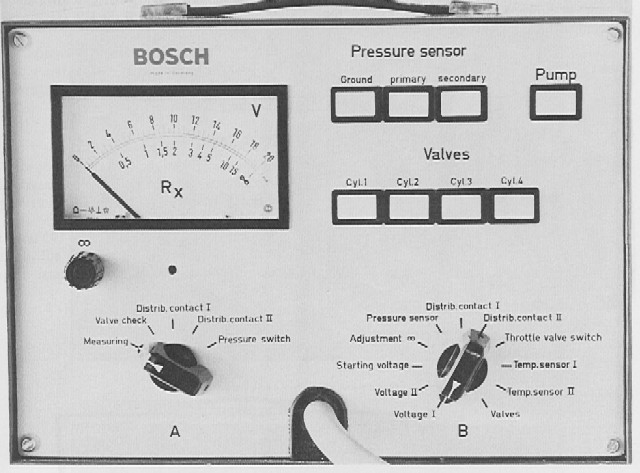

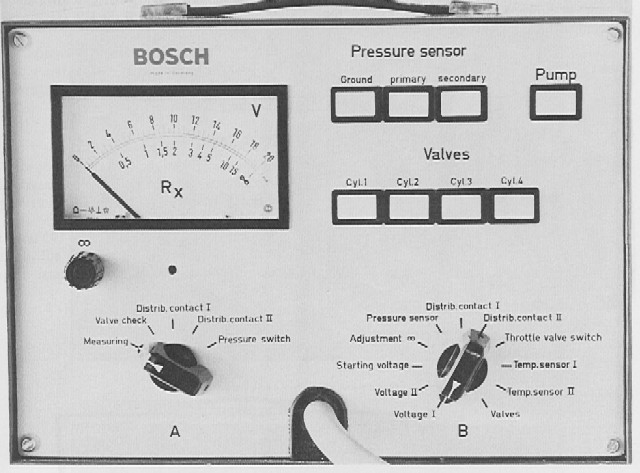

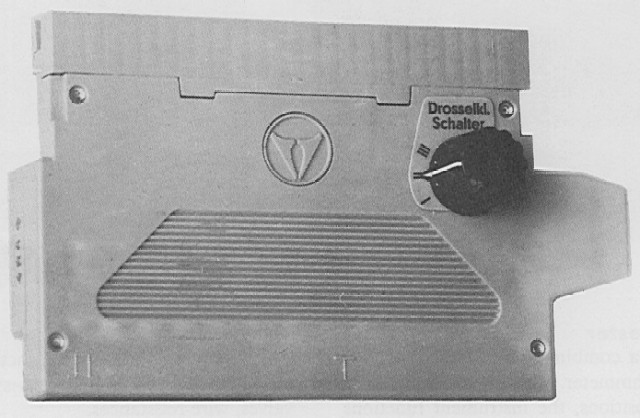

This was the first tester model that Bosch provided for D-Jetronic. Most of the tests it supports can be accomplished with a break-out box and a DMM. The meter measures ohms or volts, depending on the positions of switches A and B. A 25-pin interposer is used to connect the tester with the ECU and the wiring harness.

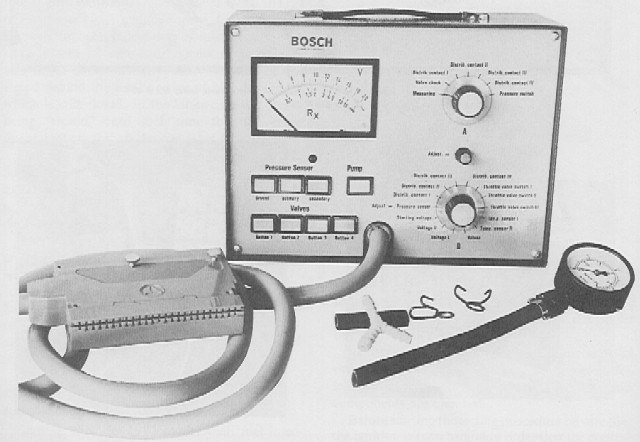

This tester is similar to the 193, except that it came with an extra kit for fuel pressure measurement and also could properly test the later model throttle position sensors.

The list of tests performed by the EFAW 193 is as follows :

Switch B position, turn Switch A to "Measuring"

Switch A position, Switch B position doesn't matter. Move Switch A to "Distributor contact 1" before starting

This was an adapter for the 193 tester to update it to work with the later model throttle position sensors.

This tester is a re-labeled Bosch tester designed for the Jaguar XJ-S, which used D-Jetronic. It differs from the Bosch testers by having a separate plug that apparently connects to the FI amplifier, which was used to drive the additional injectors on the 12-cyl Jaguars. Other than that, it is functionally equivalent to a Bosch EFAW 228 tester, refer to the test steps above for details. I have finally acquired a manual for this tester off of Ebay and I'll post any useful info I find. I sold this tester in early 2002.

Lucas also sold a later version of this tester with a set of adapters that enabled the use for L-Jetronic and Lucas P Injection, used on later cars.

The VW 1218 is a highly capable tester designed by Grundig for VW. Output from the tester is of a "go/no-go/caution" nature, with green, red, and yellow lights signifying if a test has been passed or failed. The advantage of the VW 1218 tester over the Bosch testers is that it does block-by-block testing of the major functional sections of the ECU, and it also does a self-heating test to evaluate the TS1 and TS2 sensors over their operating range. This tester is the best way to evaluate an ECU, it can detect even the most obscure ECU problems. It can be rented from Pelican Parts.

The tester is designed to handle 914's from 1970 through 1972, and VW T3 and T4 models from 1968 through 1972. People have used it on later model 914 motors, it seems to work, but there may be some issues. I've used my tester with my 1974 FI setup (0 280 000 044 ECU) and it passed tests 1 through 13 just fine - haven't had time to test it on the other settings.

The list of tests performed is as follows (the numbers correspond to the test selector switch position):

This tester is the hydrogen bomb of D-Jetronic testers. It was sold by EFI Associates in Southern California in the late '70's. EFI is now out of business, but it was run by Luis Eros (deceased) who others acknowledge as the ultimate D-Jet guru in the US. They also produced a tester for the L-Jetronic system called the AFC Analyzer. Anybody out there who has more information on the history of EFI Associates, or has a line on either used MPC or AFC Analyzers, please contact me at pbanders@yahoo.com .

It does all of the static tests and ECU tests of the other testers, plus it can measure injector pulse width directly. Using documentation that comes with the tester, you can verify under operating conditions if your FI system is delivering the same pulse widths as the factory settings. It also allows you to adjust mixture while running, and use the pulse widths noted to re-adjust the pressure sensor to duplicate. Retail price for the tester around 1977 was about $2000.

Unfortunately, my tester has a problem with the circuit that creates the trigger contact pulses needed to simulate engine speed conditions when performing the "engine off" tests. I hope to fix it when I get the time to trace the circuit. It works in position 1 with the motor running, providing pulse width duration (resolution of 0.01 ms), mixture control, and the other test functions listed below. I acquired a second MPC Analyzer in mid-2002, which has the EXACT same problem - which leads me to believe the problem is with me! I will be investigating further in late 2002 to see if I can figure out what is going on.

There were at least two predecessors to this tester which are much cruder in their design and implementation, but provide much of the functionality, see below for the 1401 and 2002 models.

There are 17 rotary switch positions that do one or more tests per switch position, all without the car running. There are also five additional capabilities that are done with the car running:

This is an early model of EFI Associates D-Jetronic tester, it preceded the Model 9100 described above. With the exception of the mixture adjustment capability of the 9100, and the more extensive documentation and test procedures of the 9100, this tester can manually accomplish nearly everything the 9100 does. My unit is functional and I've tested it on my car - it measures the injector pulse width under nearly any operating condition. The tester can simulate the TPS, trigger contact points, and both temperature sensors, using the three knobs on the lower right. By using a vacuum pump to set the MPS, any load and engine speed condition can be simulated. As I describe below, it should be possible to duplicate the functions of this tester by using a split breakout box, with a trigger contact simulator and a pulse width meter (note - which is pretty much how the Far West tester below works).

The 1401 also provides the ability to do precision flow testing of individual injectors (using the banana plug outputs on the top right of the tester to drive individual injectors), and can be used when the car is running to measure injector pulse widths under actual operating conditions. The "Injection Duration" plug outputs a cleaned-up injection waveform that is easily read on a scope or can be connected to a DMM with pulse width measurement capabilities. I'm not sure what the "Temperature Sensors" output does, and the "Internal RPM / Points Test" outputs are for the trigger contact simulator outputs. In combination with a shop-quality gas analyzer and a chassis dynamometer, full characterization of the system under all load conditions can be performed.

Another mode of operating the tester is as a bench-top simulator for testing ECU's and MPS's. A 12V battery is used as a voltage source.

This is a later model than the 2002. My unit is roached - big internal wiring harness melt-down, dead gauge, and I didn't get any documentation or interface cables with it. Too bad, as it offers some additional functionality over the 1401: more RPM settings, line 16 and 24 voltage indicator lights, better control of the fuel pump, etc. I hope to get ambitious enough to repair it in the future.

This is a nifty tester I know almost nothing about the history of and had never heard of until it popped up for sale on Ebay. I received it with no documentation, but due to the clever use icons on the front panel, it's pretty easy to figure out what it does and how to set up the tests. Each of the main switch positions has a color associated with it that tells you what range to look at on the meter. Various switches on the unit have icons that are used on the main switch to indicate how you perform the specific test.

This tester differs from all of the other testers on this page in that it does not have a pass-through type of connector that interposes the tester between the wiring harness and the ECU. It connects only to the wiring harness, and does not test the ECU at all. Instead, the Janbo has it's own onboard ECU that does the basics of what the D-Jet ECU does, called the "Pee Brain". Using the Pee Brain, the Janbo can do a dynamic test of the manifold pressure sensor over a range of vacuum from 0 to 15 in. Hg. You can even run the car with the Pee Brain! In this mode, the Janbo gives you direct control over the mixture - I'm not sure what you do with this information, though. Like the MPC Analyzer, it may support a way of recording the pressure sensor response at a specific vacuum level, permitting you to adjust the pressure sensor to that level to achieve the same mixture.

There is a toggle switch on the back for switching between 4/6 cylinder and 8 cylinder applications. The tester uses a 1.5 V "D" cell to power the ohmmeter.

The list of tests performed is as follows (the numbers correspond to the test selector switch position, starting from "off" at the bottom and turning the switch clockwise):

Similar to the Janbo 112, manufactured by Kent-Moore Instrument Company of Ohio. While the "D" designator would imply that this is a later model of the Janbo 112, it lacks some of the functions of the 112 (e.g. MPS primary and secondary resistances) and seems geared towards 1970 and earlier applications. It's also clear that this is a Janbo tester, as the copyright on the panel meter is from "Janbo, © 1972". The tester uses a 1.5 "D" cell to power the ohmmeter.

I received this tester in poor condition and am in the process of refurbishing it. The panel meter is functional, but needs replacement. All of the functions work as expected. The lid contains instructions, similar to the Janbo 112's. The "Run and Dwell" test is similar to the "Pee Brain" mode of the 112, all that is said is that the trigger contacts "dwell" should read the same in the group 1 and group 2 switch positions.

[better picture coming....]

Yet another variant of the Janbo tester. Made by "Ditron Industries, Inc." of Mission Viejo, CA. I have found no information at all on this company from the web. From the manual, it is clear that this tester was derived from the Janbo, as the tester is inadvertently described as the "Janbo tester" at one point. Differs from the Janbo in that it does not require a battery to power the ohmmeter, apparently using the car battery as the source.

I received this tester and the L-Jet version (see below) in perfect condition. I am checking them out and will likely resell them on Ebay soon (2/26/03). The tester is designed for all 4, 6, and 8-cylinder D-Jet applications. Like the Janbo, this tester does not test any ECU functionality and actually substitutes for the ECU while performing running tests.

[better picture coming...]

Got this along with the 812D above. There are very few L-Jet testers available, and they rarely show up for sale at auction. The 811L is a very capable tester, it would be ideal for a 914 1.8L owner, or other L-Jet system owners. My tester is in extremely good cosmetic condition, but I cannot test it functionally as I do not own an L-Jet car. I'll be putting it up on Ebay soon, too (2/26/03).

Like the 812D, this tester substitutes for the ECU and does not test any functionality of the ECU. The manual also includes procedures for adjusting the air flow meter.

This tester appears to be a competitor for the EFI Associates testers (similar name, and built in the same city and zip code). I have no history on it at all, bought it on Ebay in fall of 2002. At first, it hardly appears to have enough connectors to be a D-Jetronic tester, no 25-pin interposer. Only a few banana plug connectors on the front, and a military-style 4 pin plug on the right. However, that's all that is needed for this to be a pretty capable tester.

The concept behind this tester is nearly identical to a tester I proposed to Jeff Bowlsby in early 2002. The idea is to build a tester that could be easily used on a car, without requiring the removal of the ECU to insert an interposer. Here's how it works - there are three main parts to the tester, a pulse width meter, a trigger contact points simulator, and a head temp sensor simulator. The injector pulse is detected by inserting a simple interposer between the wiring harness and a single injector, and running the hot lead to the tester (third banana jack from the right). The trigger contact points simulator is connected by pulling the harness plug on the distributor and inserting two leads (the two right-most pins on the military connector far right). The head temp sensor is connected by plugging a lead into the wiring harness connector for the sensor (second banana jack from the right). Connect the unit to the battery and you're done.

The unit can be used with the car running or off. When the car is off, the trigger contact simulator simulates the car running at about 2750 rpm. Load is simulated by pumping the MPS with a hand vacuum pump. The injection time can be read directly, enabling calibration of the MPS based on a table of vacuum levels and corresponding injection time ranges. In this mode, the head temp sensor simulator provides a resistance equivalent to that of a fully warmed-up motor. I compared the measured injection time to my EFI Associates 1401 tester and they were the same to better than 0.1 ms. The tester also has a mode that allows you to count the injection pulses due to the opening of the TPS, verifying that all 20 traces are active. Injection times are read to a resolution of 10 microseconds. Verification of the lengthening of injection time at cold engine temperatures is done by pressing the cold engine button above the input for the head temperature sensor. There is also an independent section of the tester that supplies a calibrated pulse to an injector for a pressure drop test (determines if the injectors are flow matched).

With the car running, injection duration is read directly. For a fully warmed-up motor, the head temp sensor simulator can be used, which provides an additional mixture control function (button and potentiometer next to the meter face). The mixture control allows you to richen the mixture and read the corresponding injection time. By monitoring either performance (e.g. dyno output) or emissions parameters (e.g. CO), the MPS can be readjusted to the optimized conditions using this function. The tester also has a neat function I haven't tried yet, which counts any dropped injection pulses as the engine is revved from idle to 3000 rpm, a great way to check if the trigger contact points are working properly. Also, any time that very long injection pulses are measured while the motor is running, the "engine flooding" light turns on, to prevent undue waste of fuel or damage.

The tester is called a "Universal" tester because it also works with AFC (L-Jetronic). In this mode, the engine speed simulation is supplied by a pulse that simulates ignition points closures (first banana plug from the right). Most of the tests above apply to AFC when operated in this mode, except that adjustments are made to the air flow sensor.

I received the tester as shown in the picture above, with no cabling. Functionally, it was in pretty good shape, I had to do a minor repair to the power LED, but the unit was pretty clean and in good shape. I built a cable set for it and have bench tested the unit, it seems to be 100% functional. I'll be trying it out on my car when I get a chance. Great unit for doing quick evaluations of MPS and ECU functionality.

Jim Thorusen, who is one of the contributors to these pages, has a small business making test sets that greatly aid the analysis of D-Jetronic problems. Here's Jim's description of his NineFourTronics Test Set:

"For Sale: New NineFourTronics fuel injection test set for the Porsche 914 D-Jetronic FI system.

Tired of needing three hands to hold meter probes inside connectors? Tired of jumpering relays with wire to test fuel pressure? Throttle position switch adjustment driving you crazy? Canít figure out what part just died?

The NineFourTronics D-Jet Test Set simplifies all of the above, and more!

Just check out these handy features:

Nineteen test points allow both metering and oscilloscope analysis of various parameters in the car's system.

Eleven light emitting diodes display injector pulses, throttle position switch condition, trigger point function, fuel pump signal, and test set power.

A built-in piezo buzzer can be switch selected to monitor various signals, such as those from the throttle position switch, allowing the idle contacts to be adjusted with only two hands, and without having to take your eyes off your work!

Two built-in potentiometers can be substituted for Temp Sensors I and II with the flick of a switch. Test points allow you to measure the resistance of either sensor while the car is running, and also allow you to measure the resistance of the substitute pots, allowing you to tailor series resistors to meet the needs of your particular car.

A "Force Fuel Pump" switch is provided to simplify measuring fuel pressure.

The unit is completely powered from the vehicle's electrical system. This means that it will work anywhere, at home, alongside the road, or at the track. It also means no batteries to change, ever!

I have re-opened my garage production line to use up the rest of the parts I have in stock. I believe that I have parts for three test sets. When these are gone, they are gone forever!

(Unit is shown with optional DVM)

A copy of the manual is available for $25.00, which will be deducted from the purchase price if you decide to order the test set."

Contact Jim at entropycat@verizon.net for additional details and current pricing

Building your own breakout box is probably the most economical way to quickly test the D-Jetronic system. While there are many ways to build a breakout box, I opted for the simplest route, where the connections are straight-through, with probe taps. This way I can run the car with the breakout box attached with minimal effect on the system, and use an oscilloscope, DMM, or other instruments to measure parameters and waveforms. I can also disconnect the ECU side of the box and test the system components directly. I built the interposer connection by using the plug from a wiring harness and the edge connector from an ECU, both attached to a piece of perfboard. Each banana plug jack is color-coded and labeled for the corresponding function. I will eventually modify the box to split out the ECU and wiring harness sides, which will permit component substitution, and will also enable me to use a contact points simulator and a pulse width meter to emulate the capability of the MPC Analyzer for a fraction of the cost and complexity (see below).

Since all of the commercial testers listed here are NLA, and if you can find one, are often inoperative, it makes sense for D-Jet owners who are interested in maintaining their cars to build their own test equipment. The simplest approach is the straight-through breaker box I describe above. To build a box like this, two hard-to-come-by components are needed - an ECU edge connector and a wiring harness plug. Ebay and your local junkyard are good sources for these components. The ECU edge connector needs to come from a dead 914-type ECU - don't get the early VW ones, they are apparently a poor match. The wiring harness plug can come from nearly any D-Jet equipped car. The project box comes from Radio Shack, as do the banana plug sockets. Total cost should be around $50. With this type of box, by connection to the wiring harness plug, you can use a DMM to test the injector resistances, contact trigger point operation, TPS switch functions, MPS primary and secondary resistances, TS1 and TS2 resistances, system voltage, start signal, etc. By plugging the ECU into the other side and starting the car, you use an oscilloscope to measure the injector pulse widths, watch for trigger contact "bouncing", etc.

A more ideal tester would split the harness from the ECU connectors. By bridging the connectors, you would realize the straight-through breakout box. A split box would permit substitution of all of the components, enabling emulation of the functions. For example, a circuit that simulates the trigger contact points could be substituted, permitting simulation of any engine speed in a static (engine not running) state. In combination with substitution of power resistors for the injectors, and vacuum pump control of the MPS, virtually any engine operation mode could be simulated and the pulse widths measured. This idealized tester describes the basic EFI Associates models, which had the added advantage of an integrated pulse meter, which is more convenient than an oscilloscope for rapid measurement of injection pulse widths.

In the future, I hope to include diagrams for the construction of a split breakout box, along with trigger contact simulation and pulse width meter circuits.

BTW, I know of at least three other D-Jet testers that I don't have listed here. One was a sophisticated unit from Sun that a guy in Australia sent me some info on, it had an integrated vacuum unit and some sort of dwell meter for measuring injection pulse widths by an analog method. And lastly, I saw a picture of a huge bench tester that Bosch developed for the engineering of the MPS and other system components. If anyone knows of other testers, please email me with details.