|

CV boots are a pain in the ass to

replace. Repeat 10X. The work isn't the problem, but the

mess. And messy ain't the word for this job.

Have lots of that orange hand cleaner crap available & tons of paper

towels.

Spray the inner CV bolts liberally with a penetrating oil/cleaner a day in

advance. Repeat in the morning.

Then jack the car up on a strange but safe angle so you can get at the inner

joint with a socket wrench. A pry bar would be better but that might

require some really lofty jack heights which can get scary.

The bolts on 87s take a medium Allen wrench. Clean them well before

you slip the wrench in. You don't want to strip one. If you

have done any work on your car, you probably have amassed a good supply of

Allens. I used an Allen head socket that allowed me to apply some

nice torque both coming & going. You have to slide right under

the car - that's why it's on jack stands with a backup jack & a tire

or 2 under the car. Safety 1st remember. You won't save any

money if you're dead.

Pull on it firmly but gradually (as opposed to sharply) & it will come

out. You might mangle the boot a bit doing this so be prepared with

a spare if you don't like living dangerously. If you are doing the inner one, it doesn't matter of

course. You can only really get at 2 bolts at a time, so you have to

roll out from under the car & reposition the hub a couple of times because you need the

car in gear with the emergency on to apply enough leverage.

When they are out, just pull back a bit of the shaft & the inner end

of the axle will drop down. Now the fun really begins.

|

|

|

|

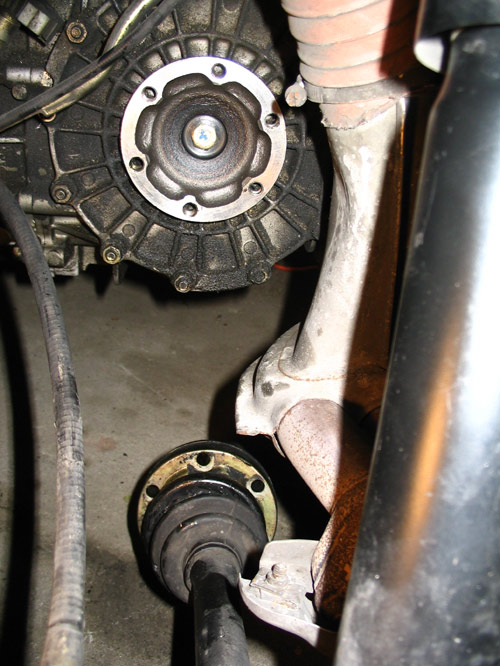

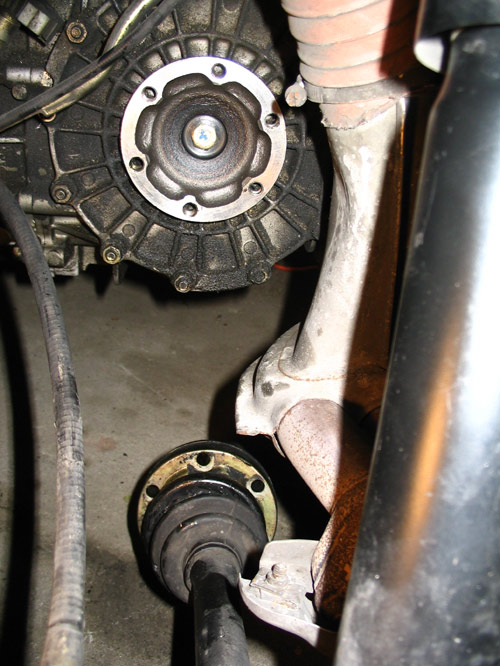

The CV joint separated &

dropped.

|

|

Remove the clamps on the front & back of

the inner boot. If stock, they might have a little metal flap that comes

thru a hole & bends down. Nice clamps btw. I ended up reusing

them because they seemed better than the ones that came with the CV boot

kit. If you are replacing this boot, just slice the damn thing &

yank the remnants off.

|

|

|

|

The CV boot clamp.

|

|

Now, you have to remove the brass colored end cap. A screwdriver on

the edge works well but it's no joy to do this or any part of this job

laying on your back. Push the CV forward & root around

in the grease for the circlip. You will have to wipe a bunch of

the black evil grease away to get at the circlip. The one on mine

did not have little holes but just had angle cut ends which the circlip pliers

dispatched with ease. When it's removed, slide the joint off of

the axle. The reality here is that you must beat on it with a

rubber hammer to slide it off. As everybody tells you, treat this

little puppy to surgical or near-surgical cleanliness. Of course,

you're laying on your back under a car with the greasiest lump of metal

you have ever seen gripped in your paws. Be careful not to play

with it too much in this position or you will have balls popping

out. While you're laying on your back . . . I did.

Clean the CV in a solvent bath & inspect the races. I would

suggest not taking it all apart to do so, since it appears to be a nice

puzzle to re-assemble. Wipe it clean & allow the solvent to

dry/evaporate completely.

|

|

|

|

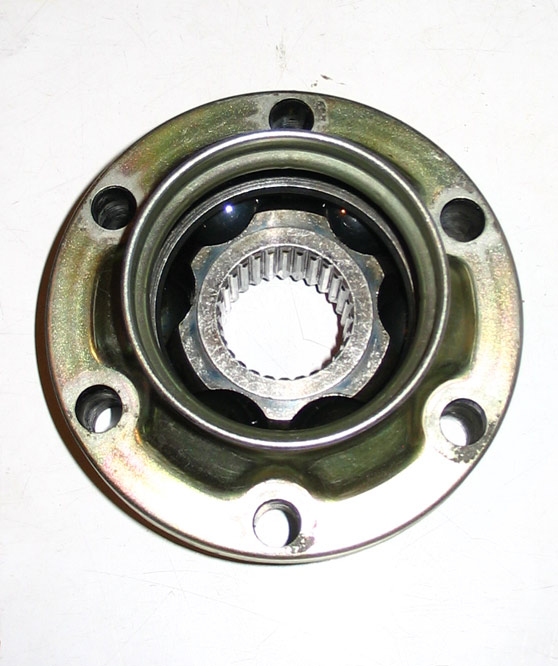

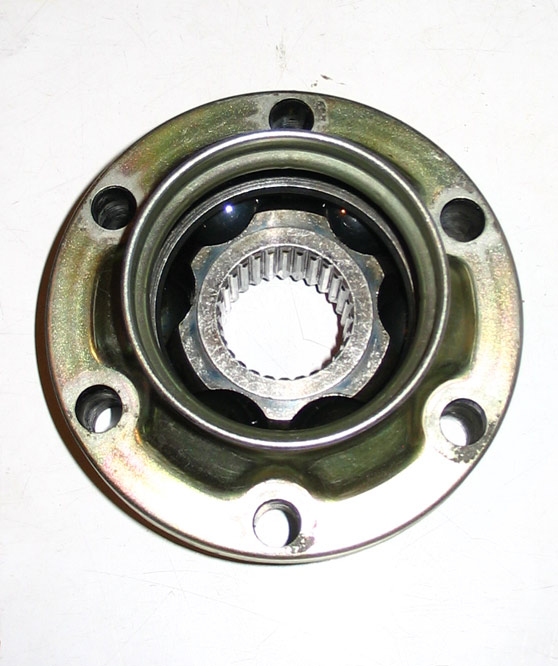

The naked CV joint.

If you roll that inner bit the wrong way, balls will come out.

|

|

If you haven't already,

remove the boot & clean the shaft. Clean it well above the

bump that holds the boot extended. Now is a really great time to

grease the boot & slide it on the axle before you forget.

Next up, I greased the CV & then pounded it back on with the rubber

hammer again. In hindsight, I would put it on without grease,

because it's not as messy getting the circlip on that way. But I

managed it the messy way.

Then lighten tap the new brass cap into place.

Install the new boot properly & clamp the ends. This job is humming

right along now . . .

Position the CV on the diff & bolt it

down not forgetting the 1/2 moon thingies. I re-used the bolts & the

1/2 moons but some guys insist on new. Torque is a problem on

these bolts since your 3 ft torque wrench won't fit under the car, so do

your best. Everybody, and I mean EVERYBODY recommends that you

check the tightness after 50 miles & again 100 miles or so after

that to make sure they stay tight. Then just keep them on the

routine maintenance checklist.

|

|

|

|

Done. The shaft is

cleaner that it looks . . .

|