It seems to be a pretty common problem: the latching motors on the front of the cabriolet top tend to break. If the gearbox binds at all, a press-fit brass gear inside the gearbox will split, ruining the press fit and allowing it to spin on the worm gear. This happened to the previous owner, and he had the entire motor swapped out for ~$500.

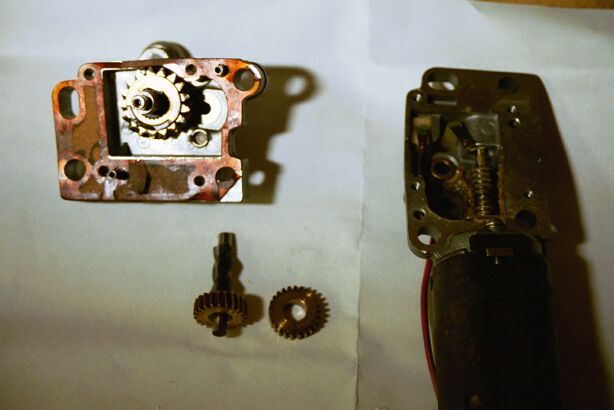

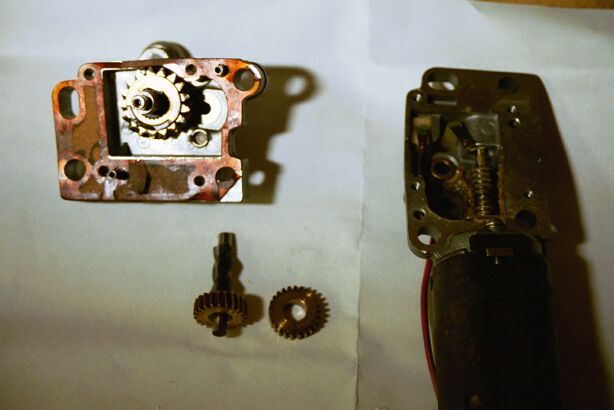

Below is the motor/gearbox that recently failed, this is what you can expect to find if/when you open yours. The worm gear on the motor turns the brass gear in question. This gear is press-fit on a screw gear that turns the large tooth brass gear. This large brass gear turns the output shaft and acts as a switch to tell the system that it is closed. Note the dark semi-circle on the large brass gear and the free floating contacts on the motor side of the gearbox. (More on this below.)

Although it is very difficult to see, the gear pictured below is split along the lower section, vertically. The fix to this is to simply find a custom gear company or a machine shop that can create and press on a new gear. The mounted gear pictured below was made at Stine Gear and Machine Co. (address below).

In addition to installing the new gear, I also put a lot more fresh grease in the gearbox, being careful not to get it on the electrical contacts within. This also prompted me to open the driver side gearbox to add some fresh grease there as well. What I found was that the driver side gearbox was a bit different (probably a newer version from the P.O.'s replacement). Instead of having free floating contacts that touch the large brass gear, a microswitch was installed along with a plastic nub to activate it. While I was in there I verified that the gear that is prone to failure is identical to the passenger side. From this I would surmise that the gear is the same for both driver's side and passenger's side as well as old style and new style assemblies.

If you have trouble finding a local gear shop you can disassemble your gearbox and send it to:

Brian charged me ~$50 for the gear, and he kept the design specs to make more. You might be able to just send him the bad gear and screw shaft it is pressed onto, but he had me bring in the whole assemble to check the fit when he was done. Give him a call and ask.