One Owner's Opinion on Sound System Replacement

After many years of adequate - but not stellar - performance the factory

10-speaker 160 watt (right! NOT) system in my 1991 928 GT was due for total

replacement. Many of the speakers were toast - the foam having rotted away.

The factory CD-2 head unit had already been replaced once with a Porsche

rebuilt unit. That lasted exactly one year and a day - just long enough for

the warranty to run out - when it, like the original, went on the fritz. It

needed to warm up for 20 minutes before it would play a CD. And if it got

too warm it wouldn't play. And of course, if you hit a pebble in the road

it would skip. Add that to 5 out of 10 speakers blown and you've got a recipe

for total lack of sound system enjoyment.

When investigating a replacement system for a 928 the first thing you

have to come to grips with is that there is no extra room in the car for

anything. You've got 8 (S4 through MY '88) or 10 (MY '89-'95) holes for

speakers. A book-sized volume in which the factory amp lives, a teeny crossover

behind each door panel, ... and that's it. If you want Big Sound you are

going to have to give up some passenger compartment space, hatch space,

shelf space (in pre-1990 models), under- or instead-of-seat space, or spare

tire space. Some folks have mounted components under seats, some have removed

rear seats and fabricated enclosures where the rear seats previously resided,

some folks have given up 50% or more of their hatch space, and some folks

toss out their collapsible spares.

Below are some links to pages detailing how other folks did the job and/or

to other useful-for-research or component source pages:

Before deciding what components to source, how the

install would be performed, or how serious a system I was going

to go for, I first decided upon my constraints.

My Constraints

- Destructive modification was to be kept to an

absolute minimum. Preferably none at all. No drilling, no saws-all,

no cutting of wires.

- Use of factory wiring as much as possible

- No loss of passenger space

- Minimal loss of hatch space

- Visually stock/stealth

Constraints number one and two are based upon the

fact that I did not want to butcher my 928. Reports of 928 electrical

gremlins are - based upon my personal experience and my perspective

of the collective Rennlist/Porschelist/PorcheFans experience - nearly

always the product of a previous owner paying someone else to install

a stereo, or an alarm, or a coffee maker, or some other electrical gizmo

in their 928. At the time of this writing I've owned my '91 for nearly

8 years and have put 60k miles on the odometer. I have not had any electrical

problems. Not one. On the other hand, my '89 came to me with a 400-watt,

custom-fabricated, massively expensively-installed sound system and

signs of a previous cell-phone installation. And electrical gremlins

like you wouldn't believe.

Constraint two is additionally based upon wanting to

run as little new wiring as possible, avoiding ground loops, and

use of the existing fused and noise-suppressed factory power.

Number three? I do make use of the rear seats. Both

for (small) people and for 'stuff.'

Four? It isn't like there's a wealth of hatch space

to start with!

The stock/stealth constraint is the simple result of not wanting to attract

attention and thieves.

The Components

My constraints ruled out a brace of external amplifiers.

I researched amplifiers for hours and hours. The best location would of course

be right where the factory amp is located. But, the factory amp is Lilliputian-sized.

I could not find a recent-vintage four-channel (or even two-channel) amp

that was as small as the factory amp. Thus, I made a pest of myself with

fellow Rennlisters and extracted opinions on powering speakers with a high-power

head unit. Opinions varied, but my take on them was that a 4x50-watt head

unit would provide adequate power for moderate listening levels. Since I

was not looking to enter any ear drum bustin' contests I settled on a hi-po

head unit as a starting point.

Speakers. Speakers. Speakers. The most important components are the speakers.

After listening to a lot of non-original sound systems and soliciting opinions

I developed a preference for MB Quart component speakers. These, like many

good speakers, come with external passive crossovers. Unfortunately, they

are not small crossovers. I spent a considerable amount of time researching

speaker and crossover dimensions trying to fit various choices into the space

available on a 928. In the end, I decided upon MB Quarts, but had to loosen

slightly one of my constraints: the collapsible spare had to go as there

was no place to mount one of the crossovers without giving up passenger compartment

space or mounting them under a seat which was something I didn't want to

do. However, once that constraint was left behind, 100% of the spare

tire well became available for additional toys. The components I chose were:

I would have been satisfied with the single-slot CD

capacity of the head unit. But, the fact that the spare tire well

became available, allowed me to add the Music Keg, and provided for

some growth room for the system if my initial design proved less-than

satisfactory.

Locations, Installation Planning, Interior Removal

- The Music Keg and left-rear crossover are mounted

in the spare tire well.

- The right-rear crossover is mounted in the factory

amp location.

- The front crossovers are mounted behind the door

panels where the factory crossovers user to be located.

- One set (Right and Left) of pre-amp level cables

are routed to the spare tire well. (Unused presently.)

|

Before I dove into the

project, partially due to my constraint to re-use as much of the factory

wiring as possible, but primarily to ensure that no wires were crossed, I

developed a wiring diagram for the system.

While I was developing the diagram, I began disassembly of the interior.

In addition to installing the sound system, I planned to refurbish some of

the interior panels and to replace some window-related components. Removing

the door panels was necessary since the factory crossovers were to be replaced

by the MB Quart crossovers. With the panels removed it was also possible

to replace plastic window guides and thereby fix the driver's side window

rattle that had been getting steadily worse. Also, I re-felted the window

guide bumpers to prevent the old worn-through bumpers from (further) scratching

the glass. In addition, some part of the vinyl on all of the removable interior

panels was starting to come loose at the edges. With the panels removed it

was possible to re-glue the edges and to easily and thoroughly clean each

panel. Lastly, having the interior out made routing the wires much easier.

In fact, without removing the panels I could not have routed the wires as

described herein.

There are a number of good reference pages for interior removal:

And then, with the diagram in-hand and the interior removed I began the

install. Below are some of the major elements not necessarily in the order

in which I proceeded.

|

|

Harnesses, and Harness Adaptors

|

To connect the head unit

to power, ground, speakers, etc., I fabricated a harness adaptor. I sourced

two male 8-pin DIN connectors. One to connect to the factory multi-wire cable

behind the head unit and one for the other end of the cable heretofore plugged

into the factory amplifier. I soldered the wires (as described in the wiring

diagram) from the head unit's multi-pin plug to the first DIN connector.

Prior to soldering the connections I slipped on a 1" long slice of small

O.D. heat-shrink insulation over each wire which were later shrunk over each

solder joint. The entire connector received a longer piece of 1/2" O.D. insulation.

As shown in the wiring diagram the DIN cable carries 6 of the required 8

speaker signals. The negative signals for the two rear speakers were terminated

in a 2-pin MOLEX plug-in connector. To connect the head unit's plug to factory

power and ground I sourced a harness adaptor from SW STEREO SPECIALISTS. I dismantled

the adaptor and mated the 6-pin power and ground plug to the wires from the

head unit's plug using Master Solderseal

butt connectors. (I also used the Solderseal connectors in a number of other

places including all the terminal connections for the crossovers and speakers.

These connectors are not cheap but they are very trick, easy to use, and

result in a bulletproof connection. The connectors slip over the end of a

stripped wire. You then take a heat gun to the connector. The heat shrink-wraps

the end of the connector around the wire with an air- and water-tight seal.

Then, with an additional few seconds of heat treatment, a band of solder in

the middle of the connector melts and flows around the stripped wire and bonds

to the bottom face of the connector.)

For the other end of the harness and for carrying the output from

the right-rear crossover through the factory wiring, I sourced four

2-pin connectors that match the factory's connectors from the amplifier

to speaker connections. For the positive speaker signals from

the DIN cable I used 14-gauge copper stranded wire. In fact, for all of

the non-factory wire, I used six different colors of 14-gauge primary

wire.

With the harness adaptors constructed, I fabricated wiring harnesses to

carry the signals that would not be carried by the factory wiring:

- A two-wire harness to carry the two rear-speaker negative

signals from the head unit adaptor to the factory amplifier location.

- A two-wire harness to carry the left-rear speaker signals

from the factory amp location to the spare tire well. One end terminated

in a two-pin MOLEX connector connector. The other using two ports of a

6-pin connector.

- A six-wire harness to carry signal to and from the left-rear

crossover to a 6-pin MOLEX plug connector.

- Two four-wire harnesses to carry signal from the front crossovers

to the front speakers in each door panel.

- A four-wire harness to carry signal from the left-rear crossover

to the left-rear speakers. One end of this harness using four ports

of a 6-pin MOLEX connector and the other end terminating in two 2-pin MOLEX

connectors.

- Two two-wire harnesses for the left-rear speakers.

- One four-wire harness for the right-rear speakers. For this

harness I re-used the factory's four-pin connector salvaged from the

old right-rear speaker using Solderseal butt connectors.

For all of the harness wire terminations, I either crimped-on 0.093" plug

pins (with a dab of solder just to be sure) for the MOLEX plug connectors,

or used Master Solderseal connectors. With the exception of the run under

the passenger seat (which I now regret not doing like all the rest) all the

harnesses were sleeved with black heat-shrink tubing.. The black tubing makes

the runs look cleaner - more factory-like. All of the harnesses were run

in-line with other factory harnesses.

The two-wire harness from the head unit, along with the control cable

for the Music Keg, and the two pre-amp level cables, were routed under the

center console carpet in-line with the factory DIN cable. Once to the floor

pan I ran the harness and cables across making use of the factory's plastic

retainers. Once to the outboard side of the passenger's side of the compartment,

the harness and cables were pulled under the carpet to the location of the

factory amplifier.

|

|

|

|

|

|

|

|

|

|

The

two-wire harness to the left-rear crossover - along with the remaining length

of pre-amp and Music Keg cable - was run from the factory amplifier location,

under the carpet, under the right-rear side panel, and then over the lower

panel to the hatch compartment. The cables were run in parallel with a factory

harness. Once into the hatch compartment I used a few tie-wraps to keep the

cables parallel to the factory's wire run. The plug-ends of the two-wire

harness consume two ports of a 6-pin MOLEX and feed the 6-wire harness

to the left-rear crossover. The other four ports of the MOLEX are consumed

by the four-wire harness that take the frequency-split signals from the crossover

to the left-rear speakers.

The four-wire harness is run under the bottom of the upper side panel

and makes use of the factory's harness guides. Note in the second picture

that the guide serves double duty. It also accepts one of the screws for

the lower side panel. The harness has to be run on the outboard half of

the guide. Otherwise when the lower side panel is installed the screw will

penetrate the harness. The same cautionary note applies to the right-side

guide and lower side panel. The four-wire harness is terminated in to 2-pin

MOLEX connectors. One feeds the tweeter, the other the 6" speaker.

|

|

|

6-inch Speakers

|

The OEM rear

6-inch woofers are integrated with concave surrounds that mate to the convex

side panel surface. The widely-accepted means of installing new speakers

is to make use of the factory surrounds. To do so, you must destroy the factory

speakers. I used a Dremel with a cutting bit and carefully cut the driver

from the surround. The MB Quart 6" speaker almost fits perfectly into

the surround - but not quite. In order to clear the screw holes in the surround

I used the Dremel cut four small half-holes at the very edge of the very-thick

and sturdy speaker housing. Then, to securely fasten the speaker to the

surround, I drilled four small holes in the surround to match a set of the

mounting holes in the speaker. Then, with four black Allan-head bolts, lock

washers, and nuts per speaker, I fastened the speaker to the surround. The

result is a totally stock-looking rear 6" speaker.

The MB quart speaker is just a bit bigger and deeper than the factory

speaker. This results in a very, very tight fit. So tight, in fact, that

once the speaker surround is screwed to the panel one (or both) of the speaker's

electrical connections may short to the chassis. (In this case it was only

the left side.) I'd already gone too far to back out. So, rather than cutting

a bigger hole in the body (a no-no, given my constraints) I simply used some

insulating tape around the connections and on the edge of the hole. This

has, so far, worked just fine. Obviously this may only be a temporary fix.

And, I'm not particularly happy with it.

If I were to (or if I have to) do this again, rather than fastening the

speaker to the factory surround, I would consider using the spacer ring

that comes with the speakers. This would require a bit heavier modification

of both the surround and the spacer ring. Also, the spacer ring is just

a bit - 1-2mm - larger in diameter and thus doesn't look exactly right.

Also, with this set-up the stock speaker grill is not usable; The MB Quart

grill must be used.Whether that is preferable is a matter of taste or one

of constraints since it moves away from a stock/stealth look. |

|

Tweeters

|

At first I thought that mounting the small MB Quart tweeters would be

a snap. I unsnapped the tweeters from the factory surrounds and then used

the Dremel to sufficiently widen-out the hole in the factory surround to

accept the MB Quart tweeters. Unfortunately, when I did a test fit on the

rear panel I realized that I had used the factory surrounds oriented upside

down. The factory surround has a thin lip around the outer diameter to allow

the factory grill to snap in place. With the surround upside down and the

surround securely screwed to a panel, the grill cannot be snapped into place.

In addition the MB Quart tweeter is ever-so-slightly thicker in the center

and, even if the grill could grip the edge of an upside down surround, the

center of the tweeter comes into contact and deforms the center of the factory

grill.

Back to the drawing board I went.

I needed to make a new surround for each tweeter. They didn't need to

be knock-out pretty. Since the surround would be hidden by the factory grill

the new surround could look a little rough. So, I obtained several sheets

of 1.0mm polystyrene plastic from a local hobby store and a gasket cutter

from Sears. The polystyrene plastic is worked-with exactly like glass - you

score it and snap it at the score. However, making washer-like cutouts is

a bit more of a challenge since in the center there's no effective way to

bend and snap.

For each needed surround I cut "washers" from the plastic in two different

diameters. The largest is about 1/8" of an inch larger than the smaller.

When glued together with plastic model cement with the larger-O.D. facing

'up' there is sufficient lip to allow the factory grill to snap in place.

Thus, with some scoring, snapping, gluing, and painting (with a flexible model

paint) I constructed my tweeter surrounds.

The last speed-bump was the tweeters for the door panels. The factory

mounted its tweeters in the doors at an angle - facing away from the driver.

I figured that the factory had a reason and since I was making new surrounds...

why not. The only problem was that the MB Quart-provided angled tweeter

mounts were a bit deeper than the non-angled variety and thus my solution

for the rear would not work. However, mounting the tweeters to the inside

of the door panel with my newly-fabricated surround rather than the outside

solved the depth problem - but not the grill attachment problem - since with

no surround on the outside of the panel there is nothing to which the factory

grill may snap on. To solve this problem I created two more surrounds. These

needed a larger center pass-through diameter to accept the larger angled tweeter

mount. The resulting solution consists of one surround on the outside

of the door panel that allows the factory grill to snap into place and one

on the inside of the door panel to secure the tweeter. The entire assembly

is held to the door panel by the factory's screws, factory's speed nuts and

the tweeter hardware provided by MB Quart.

|

|

|

|

Front Speakers

|

Installation of the 4-inch

speakers in the door panels resulted in the only violation of constraint

#1 (No drilling, cutting, etc.) The MB Quart 4-inch speakers are deeper than

the OEM speakers. To mount them on the panels you have to use the spacer

rings provided with the speakers. The mounting holes for the spacers do not

line up with the existing holes in the panel. You have to drill four new

holes in the panel. However, if for some reason, the factory speakers needed

to be re-installed the new holes will be covered from sight by the factory

surround and speaker grill.

To finished the door panel speaker installation, I clipped the spade connectors

attached to the new tweeters and replaced them with plug-in pins for a 2-pin

MOLEX connector. The factory's wire guides hold down the harness from the

crossover. The crossover is mounted to the same points as the factory's

crossover with the aid of two metal corner braces each drilled appropriately.

The crossover is held to the corner braces with an Allan bolt, nut, and

lock washer. To connect the crossover to the factory wiring, I violated

constraint number #1 again; I clipped the spade connectors and used two

Soldermaster connectors.

Since the MB Quart spacer is used, the MB Quart speaker grill must be used

instead of the factory grill. I elected - for the moment - to not snap the

bright red MB Quart advertisement into the holes provided in the grill.

The entire result looks good and stock - at least to those not intimately

familiar with 928s.

|

|

Right-Rear Crossover

|

The right-rear crossover was mounted in place

of the factory amplifier. I unscrewed the factory's mounting brackets and

re-used them. One strip of thin metal was used to connect the two brackets

in an "H" pattern and provide a point to mount the narrower crossover.

|

Left-Rear Crossover and Music Keg

|

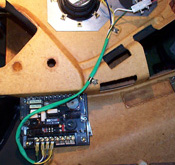

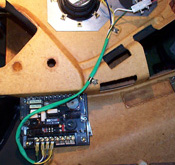

I constructed a baseplate from MDF to securely

mount the Music Keg and the left-rear crossover . I used a piece of cardboard

- cutting and shaving it to fit in the spare tire well - as a template for

the MDF. I made sure to allow for clearance for the ground cable and the

audio cables. The plate was covered in green fabric and I installed two handles

to make lifting the plate easier. There's enough slack in the audio leads

to allow the plate to be lifted, moved to the right, and placed on the gas

tank without disconnecting. The 6-pin MOLEX plug allows the crossover to

be disconnected. The Music Keg unplugs easily, and the pre-Amp cables are

unused. The entire assembly can be removed from the car if necessary.

The open area to the 'South' of the Music Keg is necessary to allow extraction

of the Music Keg's hard disk. The open area in the 'South East' corner is

growth room for an amplifier. Since the MB Quart crossovers allow bi-amplification,

adding a multi-channel amp and increasing power to the speakers is possible

as an 'addition.'

|

Epilogue

The system sounds very good. The MB Quart speakers have a nice warm sound.

The imaging is good. The bass is poor. A tiny bit of additional power would

be nice. It is

way better than the factory's system when new. I'm

going to live with the system for a while and then decide if more power

and bass is better than a supercharger kit. (Not likely.)

I have growth room for a right-sized amplifier. But, I out-smarted myself

a bit; I thought I was leaving sufficient room on the baseplate for almost

any reasonably-sized amplifier. I was wrong. As it turns out though

Audiobahn

makes a lot of amps in different sizes and flavors.

Also, I'm eyeing a

powered

and enclosed subwoofer. And the just-in-case pre-amp cables are already

plugged into the subwoofer outputs of the head unit.

The sound system is now very modular. Components (except for those in the

door panels) can be easily removed and unplugged, substituted, augmented,

etc.