i got this DIAL METER

at AUTOZONE for 30 bucks... I may return it after Im done but it

is acutally a handy little tool

i got this DIAL METER

at AUTOZONE for 30 bucks... I may return it after Im done but it

is acutally a handy little toolCRANKSHAFT END PLAY & THRUSTBEARING HEALTH

This page shows the steps I took to measure the amount of play in my crankshaft and the health/condition of my thrust bearing.

This all came about from numerous postings on the Rennlist about THRUST BEARING FAILURE and how to prevent it.

In a nut shell this problem is mainly with AUTOMATICS and occurs when the central shaft inside the torque tube expands and contracts when loads are applied upon it under normal driving....the problem again arrises when these loads arent sufficiently released. The forces are meant to be absorbed by the flexplates to some degree and by the THRUST BEARING........BUT apparently the force of this expansion and contraction eventually causes the THRUST BEARING inside the engine block (on the crank shaft) to fail.. Once the thrust bearing fails as a result of this, the forces will grind away at the engine block where the THRUST BEARING sits. The result is $$$$$$$$$$$$ and a new engine!!

The measurement was easy to make (i believe i did it correctly) and i used the following excerpt from an EMAIL of RENNLIST MEMBER who performed the same procedure on his 88s4.

"After the pinch bolt is loose then put the dial indicator on the flywheel, (not the flexplate). Pry the flywheel back and forth to check the crankshaft end play. The spec for later engines is .0024" to .0076". Wear limit is .016" If your end play is more than .016", then you are experiencing "Thrust \par Bearing Failure"."

Earl Gillstrom 88 S4 5 Speed Crankshaft end play .007" at 91,000 miles "

(Earl, I hope you dont mind me quoting your reference!!)

i got this DIAL METER

at AUTOZONE for 30 bucks... I may return it after Im done but it

is acutally a handy little tool

i got this DIAL METER

at AUTOZONE for 30 bucks... I may return it after Im done but it

is acutally a handy little tool

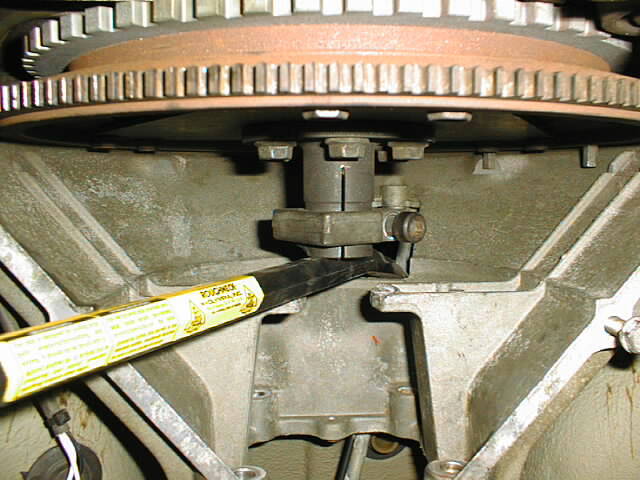

With the lower flywheel housing removed i first

pried the entire flywheel assembly towards the engine (with a

14inch crow bar). This prying is absorbed to some degree by the

flexplate(at this location) but you will see that the flywheel

will eventually move a bit. I applied pressure at 3 points( this

is #1) to assure the flywheel and crankshaft did indeed move.

With the lower flywheel housing removed i first

pried the entire flywheel assembly towards the engine (with a

14inch crow bar). This prying is absorbed to some degree by the

flexplate(at this location) but you will see that the flywheel

will eventually move a bit. I applied pressure at 3 points( this

is #1) to assure the flywheel and crankshaft did indeed move.

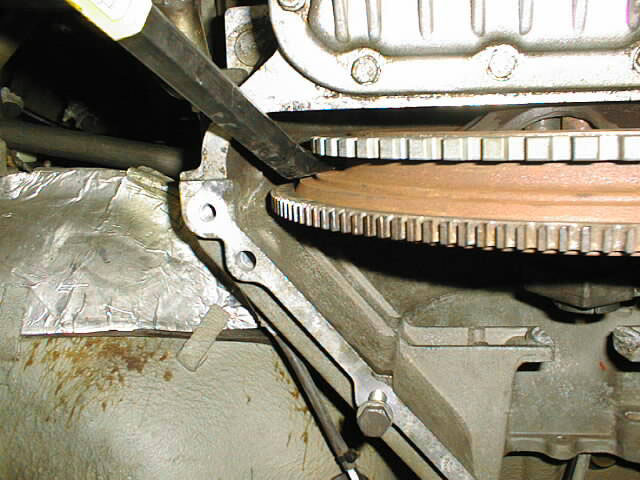

(this is #2) prying the other part of the flywheel

(this is showing prying in the other direction...but you get the

idea)

(this is #2) prying the other part of the flywheel

(this is showing prying in the other direction...but you get the

idea)

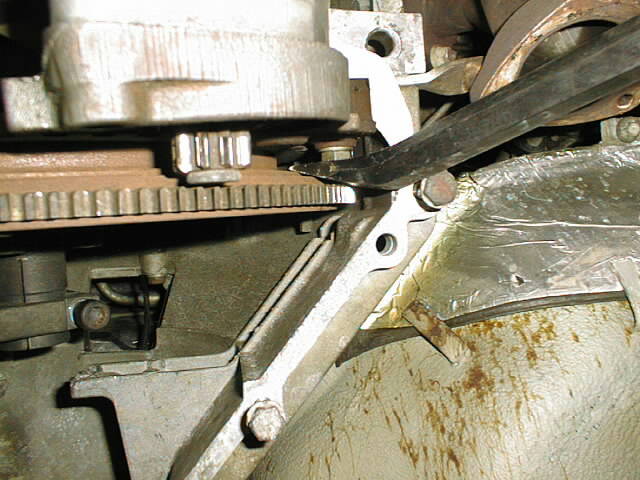

(and #3) this is the other area i applied pressure

(too move both forward and aft)

(and #3) this is the other area i applied pressure

(too move both forward and aft)

Once i was assured the flywheel was as far back as it could go towards the engine i placed the dial meter on a suitable spot seen below and took my first measurement. The key here is to get a difference between 2 measurements.

Each increment on the dial is .001"

#1

Using the same areas as before to pry the crankshaft FORWARD, I now moved the flywheel AFT.....once this was done i applied the DIAL METER in the same spot and obtained a new measurement. I repeated these steps a series of 3 times to determine the accuracy of my methods. I also tried various other areas to get measurements but in the long run they all pointed to the same NUMERICAL DIFFERENCE in the end.

Below is the second measurement.

#2

The math now is simple...subtratct #1 reading from #2 and you end up with a value that should be the amount of play in the crankshaft thrustbearing.

BEFORE = 72

AFTER= 79

DIFFERENCE=ENDPLAY= 7 (in this case it is .007" .....i left all the zeros out....darn higher math!!! : )

According to Earls quote above from the manuals and his work , (correct me if im wrong) this value is with in specs!!!!

PHEWWWWWWWW!!!

Oddly enough i came up with the same value as he did .007" ...and my car is just hitting 78,000mi

The goal now is to periodically check this value as well as releasing any preload that accumulates on the Thrust Bearing by releasing the clamping collar.

SIDE NOTE: Besure to check the specs for RE-TORQUIING the pinch collar bolt...i believe PORSCHE now recommends that the bolt be tightened to 110% of book value (check for yourself first)

Anyone with any input please let me know......