"my future 'lil assistant"

CHECKING YOUR TIMINGBELT and TENSION

The camshaft timing belt on the 928 is probably the achilles heel of the motor. If the belt fails or slips enough teeth, you WILL come to a stop and may be in for A LOT of damage to both your motor and wallet. There has been discussion on which motors are interfence motors and which ones arent, i'm not going to get into that. My car, the pictures and the procedure below are for an 87s4 with 32valves and IT IS AN INTERFERENCE MOTOR (as are ALL 32 valve engines)! If the belt breaks or slips YOU WILL do damage (unless you are extreeeeeeeemmmmmmly lucky). Therefore, routine inspection of the timing belt, its tesnion and running gear are essential in helping you avert a possible disaster!!!

I hadn't intened on doing this page yet , as the recommended retension check is at 1500 miles after the new belt goes in, but during the installation of my timing belt, somehow, the tension warning connector behind the center timing belt cover became unhooked. This situation caused a TENSION WARNING exactly 3mins after EVERY start. In order to reconnect the wire to the sensor I had to remove the passenger side timing belt cover, which is bascially the process you go through to check your tension.....hence this quick page.

The time to remove all the items below took me exactly 25 minutes...install was roughly the same ...so give yourself an easy hour or a bit more. I had the advantage of having just removed all these parts during the installation of my belt, so every thing was clean, the bolts were easy to remove and the procedure was fresh in my mind. YMMV!!

1) jack and

support the car....place catch pan under radiator drain.

1) jack and

support the car....place catch pan under radiator drain.

2) remove

coolant tank cap and then remove the BLUE radiator drain plug and

drain the coolant from the radiator. You're doing this so you can

remove the upper rad. hose for easier access to the belt cover. These first 2 steps are optional I believe

as i think the job can be done with out removing the upper rad.

hose.....the more room the better i say!

2) remove

coolant tank cap and then remove the BLUE radiator drain plug and

drain the coolant from the radiator. You're doing this so you can

remove the upper rad. hose for easier access to the belt cover. These first 2 steps are optional I believe

as i think the job can be done with out removing the upper rad.

hose.....the more room the better i say!

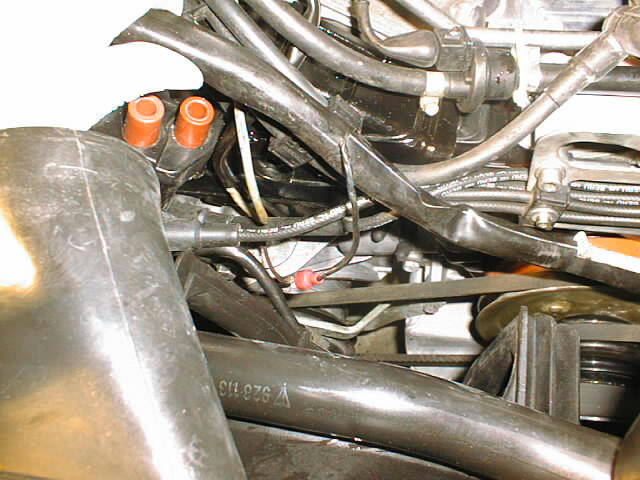

3) this

gives an overview of what I FOUND needs to be removed. (green

dots)....upper radiator hose clamps and hose...coolant fill line

at the engine...wiring harness allen bolts...plug wires from

distributor....distributor...oil dipstick tube....and the belt

cover...YMMV. The wire that leads to the AC will have to be

disconnected also, it makes for easier access and it becomes a

VERY good time to check the connection! The rest of the items

like plug wires ,wiring harness and coolant lines can be moved

and zip tied out of the way. The more room the better in this

engine compartment!! You may be able to get away with removing

less, but as you will see, i had a nice open area to work with

when done.

4) removing a

coolant hose.

4) removing a

coolant hose.

5) loosening

the bolts for the wiring harness. Once removed the harness can be

lifted and zippped tied out of the way. The plug wires at this

location shouldnt have to be removed. YMMV

5) loosening

the bolts for the wiring harness. Once removed the harness can be

lifted and zippped tied out of the way. The plug wires at this

location shouldnt have to be removed. YMMV

6) center of

the picture is the wire to the AC clutch (RED connector) which

should be un hooked. (and cleaned!!!) . Also you can see how the

wiring harness can be lifted up and out of the way.

6) center of

the picture is the wire to the AC clutch (RED connector) which

should be un hooked. (and cleaned!!!) . Also you can see how the

wiring harness can be lifted up and out of the way.

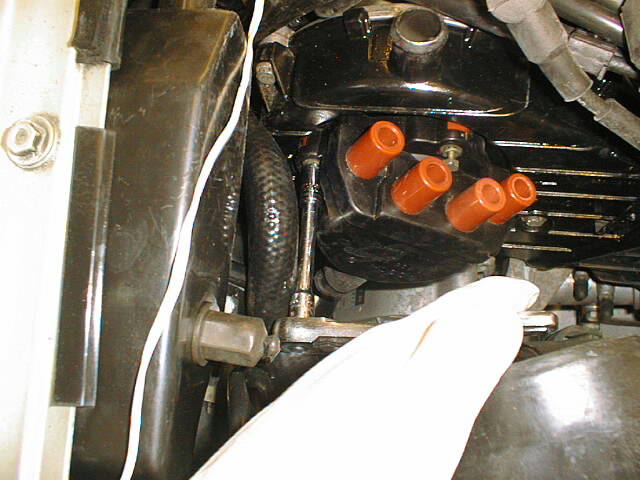

7) you MAY or

MAY NOT have to remove the distributor. I found the timing belt

cover was just too tight of a squeeze on the radiator cooling fan

housing to come out easily with the distributor attatched.......

3 bolts.....8mm i believe. Note the plug wires etc. ...zip tied

out of the way, one more free hand!.

7) you MAY or

MAY NOT have to remove the distributor. I found the timing belt

cover was just too tight of a squeeze on the radiator cooling fan

housing to come out easily with the distributor attatched.......

3 bolts.....8mm i believe. Note the plug wires etc. ...zip tied

out of the way, one more free hand!.

...just

a shot of the socket on the dist. bolts. they are some what tough

to access.

...just

a shot of the socket on the dist. bolts. they are some what tough

to access.

a shot

of the cover removed and the whole reason i had to do this

job....the timing belt tension warning wire wasn't hooked up

(gold connection in center of picture)! this created an

UN-POWERED condition in the circuit thus triggering the warning

exactly 3 minutes after EVERY start. Removing one bolt on the

center timing belt cover and some manipulation of a few fingers

and i got it back on again...problem solved!!!!!!

a shot

of the cover removed and the whole reason i had to do this

job....the timing belt tension warning wire wasn't hooked up

(gold connection in center of picture)! this created an

UN-POWERED condition in the circuit thus triggering the warning

exactly 3 minutes after EVERY start. Removing one bolt on the

center timing belt cover and some manipulation of a few fingers

and i got it back on again...problem solved!!!!!!

a nice shot of

the room i had to work with once the items listed above were

removed and secured out of the way.

a nice shot of

the room i had to work with once the items listed above were

removed and secured out of the way.

BELT TESNION IS MEASURED AT 0' TDC ONLY!!!!......................

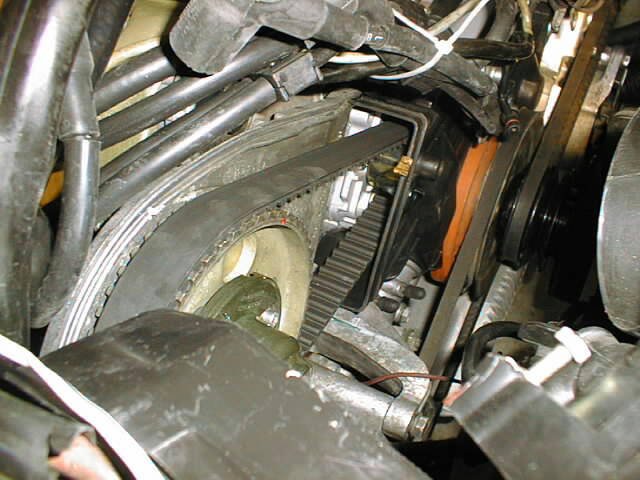

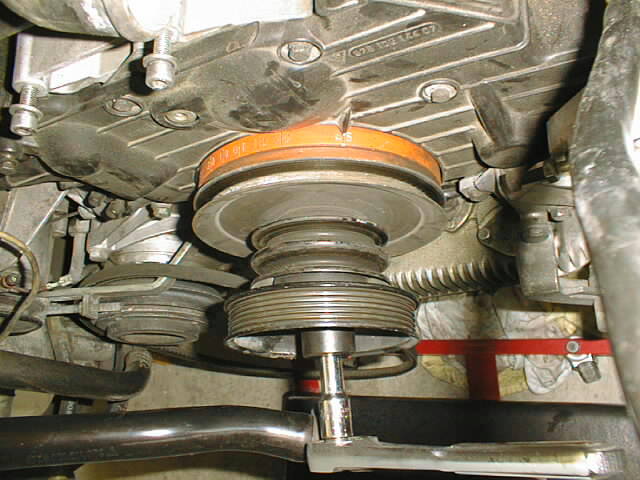

wrench on

crank pulley.........pulling through CW

to 0 'TDC (45' is shown in this

picture)

wrench on

crank pulley.........pulling through CW

to 0 'TDC (45' is shown in this

picture)

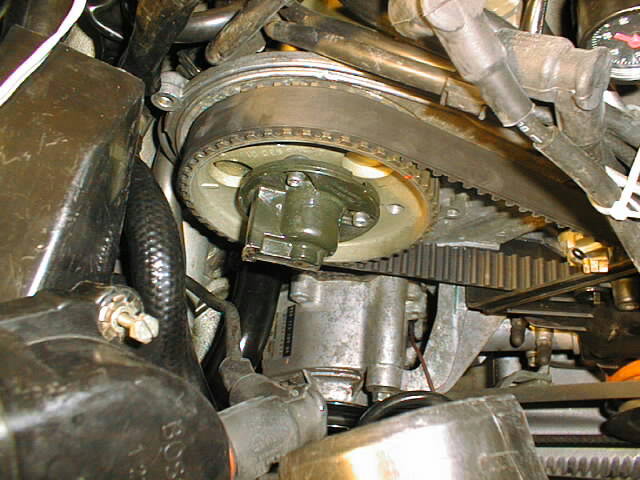

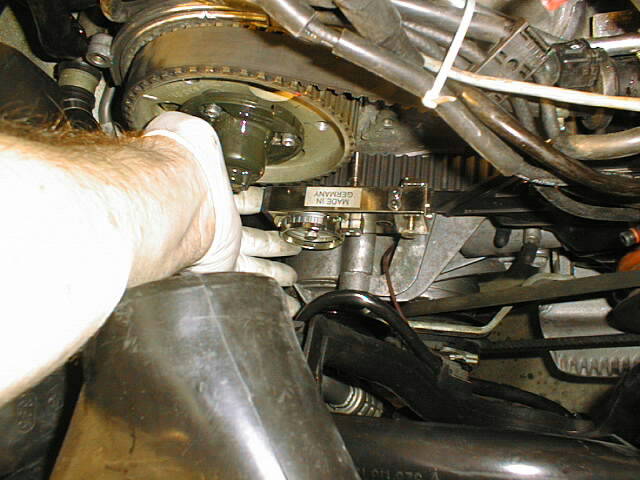

at TDC

on the crank you should be able to see that the timing notch on

the back of your cam sprocket (hidden ,but

GREEN in this picture) and cam backing plate(shown in RED)all line up. ...this is when

you take your belt reading!

ABOVE:

Placing the "official" timing belt tool on the belt.

There is NOT much room to work with here. (Could you do it with

the radiator hose in the way???)You will find the tool will only

fit on 1 or 2 teeth of the belt because of the space

involved.....the right side of the tool will almost run up

against the center T-Belt cover. (note in this picture the cam

sprockets are NOT at '0 TDC"...it is referencing appx tool

placement only)

ABOVE:

Placing the "official" timing belt tool on the belt.

There is NOT much room to work with here. (Could you do it with

the radiator hose in the way???)You will find the tool will only

fit on 1 or 2 teeth of the belt because of the space

involved.....the right side of the tool will almost run up

against the center T-Belt cover. (note in this picture the cam

sprockets are NOT at '0 TDC"...it is referencing appx tool

placement only)

Wally Plumley of 928 Specialists has a great write up on the 928owners club page on a timing belt change as well as some good details on how to use the official factory tool (click the link above to go)

Some quick tips....

BE SURE TO CALIBRATE THE FACTORY TOOL with the CALIBRATION BAR. (4.0)......

USE A CONSISTANT PROCEDURE WITH THE FACTORY TOOL TO GET A CONSISTANT READING....

THE ENGINE MUST BE AT " 0 TDC" WHEN MAKING BELT TENSION READINGS.....

THE ENGINE MUST ONLY BE ROTATED CW to TDC EACH TIME.......

TURNING THE ADJUSTMENT SCREW ON THE TENSIONER CLOCKWISE TIGHTENS THE BELT....

DONT FORGET TO SET THE LOCKING NUT ON THE TENSIONER ADJUSTMENT BOLT WHEN DONE...

ABOVE ALL!!!! DO NOT....DO NOT , JUST TIGHTEN THE BELT UNTIL THE WARNING DISAPPEARS!!!!!!!!!!

.....after you take a few readings, rotate the engine through 2 revolutions of the crank to TDC again and repeat the measurements (ONLY ROTATE THE ENGINE CW...use a 27mm socket on the crank pulley bolt and a cheater bar to help overcome compression, unless you remove the spark plugs)...you are looking for constistency in the readings you get each time. On my car an 87$4 the values are 5.0-5.3 for a properly tensioned belt.

When using the FACTORY tool, I found it to be VERY sensitive to twisting of the belt. If you twist the tool on the belt when making the measurement it will be slightly different each time. You also dont want to let the tool rest on the air pump direcltly below it. Its is a chore to get a good reading and a consistant one!!! I havent used the Jay Kempf aftermarket belt tool but in this application it would be A LOT easier to use than the factory tool im sure!!! BELOW is a picture of the Jay Kempf aftermarket tension tool in action , the picture is courtesy of John Pirtle's web page (he has a great timing belt write up you should look at also!!) Click the image to get a JAY KEMPF tension tool!!!! You can also rent either timing belt tool from www.928intl.com

After you are satisfied with your belt tension settings you can clean up the front of the motor a bit, double check things and "button" it all back up...basically just a reversal of the procedure. You can now drive around with some peace of mind knowing you have atleast checked the health and the tesnion of your timing belt! FYI...the engine doesnt have to be at redline for a belt to break or slip...it can happen just sitting at a stop sign!!

All

back together....this shows how i went about filling the radiator

again. To avoid spills i used a small hose and placed it down in

the larger one. Once full i reconnected the hose and then filled

the coolant tank. If you drain your coolant be sure to monitor

your engine temp and coolant level after start up....it is VERY

easy to get a bubble in the system that can cause you some

probelms.

All

back together....this shows how i went about filling the radiator

again. To avoid spills i used a small hose and placed it down in

the larger one. Once full i reconnected the hose and then filled

the coolant tank. If you drain your coolant be sure to monitor

your engine temp and coolant level after start up....it is VERY

easy to get a bubble in the system that can cause you some

probelms.

Looks clean doesnt it!!! Amazing what you can accomplish when you install a new timing belt and water pump! CLEAN CLEAN CLEAN!!

Holding it

like some sort of game fish i just caught!!!! Here is a shot of

the old timing belt, SNIPPED in half...I'm 5'10"

Holding it

like some sort of game fish i just caught!!!! Here is a shot of

the old timing belt, SNIPPED in half...I'm 5'10"

Hope the info helps...get out and CHECK IT!!!!

Tony

Click the logo for parts by....