Tom Tweed's Boatbuilding Pages

Page 4- Turning the Hull

When everything that could be done at this stage on the outside of the hull was finished, it was time to turn the hull over and start on the inside structure. This called for a party. A few cases of beer, a buffet lunch and as many friends as I could get to show up one saturday afternoon made short and easy work of it, actually.

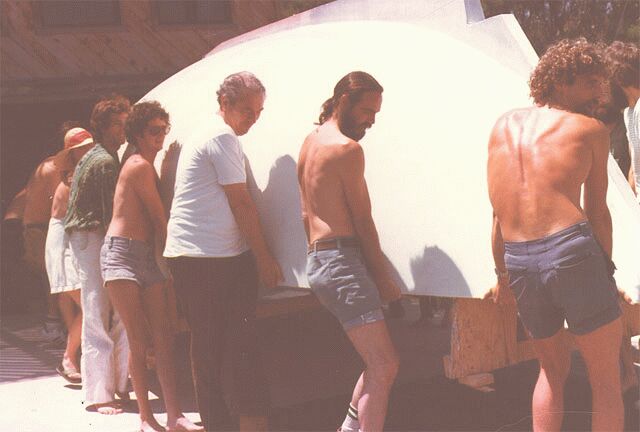

Once most of the temporary molds were removed and the rest loosened from the strongback, the hull was surprising light, and we just lined up on each side of it, lifted, and walked it out of the garage, taking care with the overhead clearance on the door, which was only about 7' high.

Once clear of the garage door, we carried it out into the driveway and set it down, rigged some safety ropes to keep it from turning too quickly, shoved some old chaise lounge cushions in garbage bags under the port side, and started rotating it over.

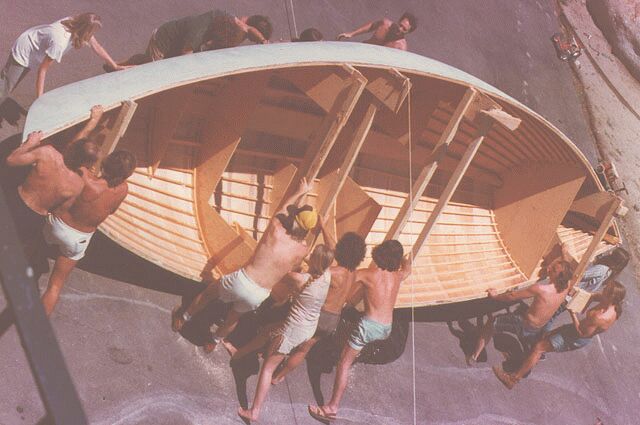

It went flawlessly, with no problems, and was much easier to handle than I expected. The first real view of the inside of the boat was a delight, as up to that time, I had only crawled around on the inside of the inverted hull between the station molds, in the dark, as if in a big tent.

Only a few temporary molds remained in the hull at this point, one at the bow and stern and one in the middle, the rest of the bulkheads are permanent- for the chainplates, bow and stern lockers, and berth framing.

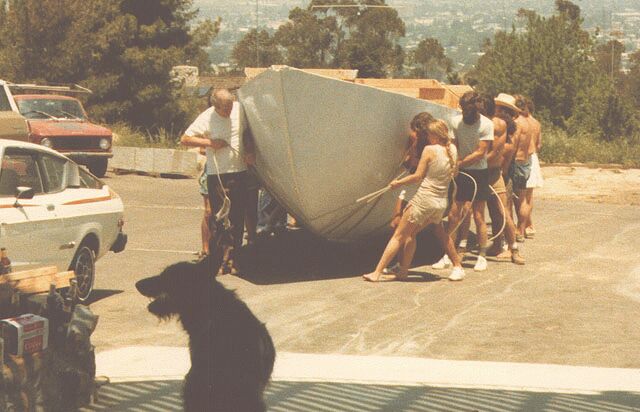

After admiring our handiwork for a bit, we snaked some 1" rope back and forth beneath the hull, everyone grabbed a loop, and we lifted it and carried it back up into the garage, where I hastily assembled a cradle under it, which I had prefabbed earlier.

In the background of the shot above can be seen the cement keel mold- it's the big slab of concrete just to the right of the red truck. This was later forklifted onto a flatbed and taken down to the foundry, where I fabricated a jig to hold 10- 1" diameter stainless bolts in the cavity formed by the keelplug (which we pulled out of it earlier, remember?), and 3400 lbs. of molten lead and antimony were poured into it and allowed to solidify. It was then broken apart with a sledgehammer to leave the one-piece keel casting.

After only a couple hours of not-so-heavy labor, due to the many hands sharing in the work, it was Beer O'Clock! That's me just to the left of the toy excavator in the foreground, with my old dog Harmon waiting for a piece of my sandwich to fall into his mouth (hopefully). My wife Maryann is behind Harmon, and my little brother Kevin (owner of the yellow excavator) can just barely be seen behind the buffet table. My Dad is in the white T-shirt on the right.

To the NEXT PAGE

Back to HOME