Tom

Tweed's Boatbuilding Pages

Table

of Contents

Page

1- The Saga Begins

Page 2- Laminating

Page 3- Coating and Keel

Mockup

Page 4- Turning the Hull

Page 5- Interior Coating and

Decking

Page 6- The Hog Fish Era

Page 7- Closing Her In

Page 8- Details

Page 9- Finish Work

Page 10- Launching

Page 11- Sailing

Page

1- The Saga Begins

The sailboat disease started a long time ago, way

back, even before the Porsche disease. I think it

was around 1960, when I was about 12 years old, that my father

bought a little bastardized Lightning class sloop and we first

learned to sail around San Diego Bay with it, bouncing off all

manner of fixed objects and other moored boats. I think the

experience convinced my Dad that a motor was a good

thing in a watercraft, as he has owned nothing but

powerboats ever since.

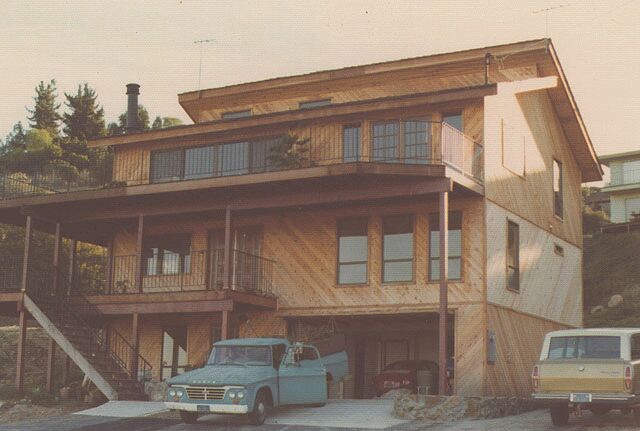

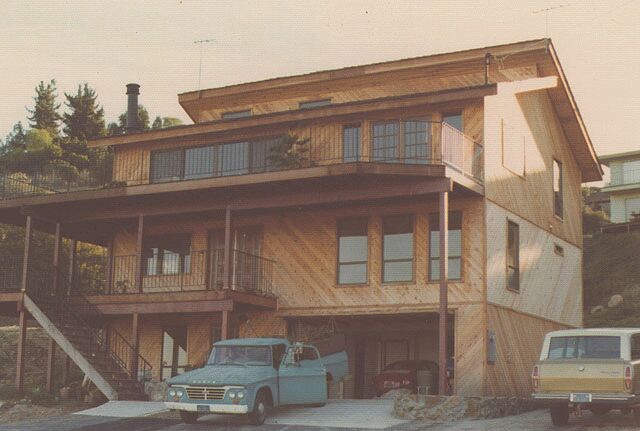

In 1976, I built a 3-story house for him on the

northeast side of Mt. Helix in La Mesa, CA, (above), and there

was a 1200 sq. ft. garage and shop area on the first floor

sitting empty when we got done. My father had always had projects

going in the garage the entire time I was growing up, usually

experimental aircraft, including 3 homebuilt sailplanes he had

designed himself and then built in his spare time, and he

suggested we put the space to use. "We've got all these

woodworking tools and a few scraps of wood left over," he

noted, "maybe a little wooden boat would be fun to build in

there."

It just so happened that I had been researching

such a project for several years, and this fact was not lost on

him. The man knows how to set a hook. Before too long, I was in

possession of the plans for a beautiful little double-ended

cruising cutter designed by Chuck Paine called a Frances 26. It

wasn't much longer before we were lofting the plans into full

size patterns and erecting a male mold on a strongback on the

floor in the garage.

The hull was to be built of 5 layers of Western

Red Cedar veneers, each layer an 1/8" thick and epoxy-glued

together in a "double-diagonal" pattern, to make a very

strong and lightweight monocoque shell of "cold-molded"

plywood, but first we needed to define the shape. The temporary

station molds above do that, and then the keelson, fixed

bulkheads, and longitudinal stringers are attached to them.

The stem and sternposts were laminated and

shaped out of Douglas Fir and attached to the keelson (also D.

Fir built up to about 3" x 12" at it's widest, thickest

point) and bent over the molds, defining the bottom curve of the

canoe-shaped hull. 1" x 1" longitudinals were scarfed

full-length and attached at bow and stern and glued to the

permanent bulkheads (but not the temporary station molds) on

about 6" centers. The picture below shows the aft section

pretty well, and you can see the permanent lazarette bulkhead

between the #2 and #3 station molds, counting from the rear.

To the NEXT PAGE

Back to HOME