Porsche 928 S4 Service

John Pirtle, May 7, 2003

http://members.rennlist.com/pirtle

Air-conditioning

During a Spring get-to-together of area 928 owners

(details) we learned about R-12 to

R-134a conversions. Our host mechanic Joel Roeder provided some history of the

changes to refrigerant, and told how the newer oils are improving R-134a

compatibility with our older R-12 systems. In short since my a/c was warm and

the site-glass was full of bubbles indicating very little R-12, he recommended

I do the following:

- install a new receiver/drier

- install a new expansion valve

- install new quick-release fittings on the system valve ports

- change o-rings along the way

- remove the a/c compressor and replace the oil

- come back to his shop for a fill of R-134a

- adjust the temperature mixer flaps

System conversion

Joel had sent me home with a bag of assorted o-rings and port fittings,

and also a bottle of Frigi-Quiet II (made by

BG Products, Inc.).

I called

928 Specialists

and learned that the Porsche receiver/drier

is relatively expensive. "However..." they sell an alternate (about one-third

of the cost) that is a similar fit and I had no problem whatsoever (this unit

is a bit narrower so I added a piece of rubber between it and the bracket

to keep a snug fit).

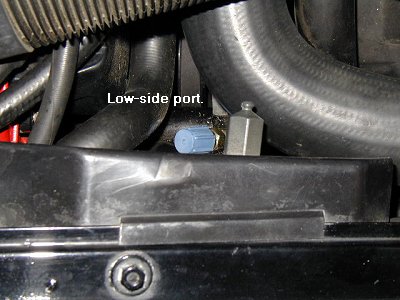

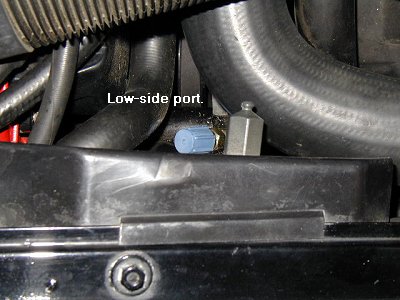

- Remove the caps from both the high-side and low-side valve ports.

Take a

screwdriver and push in each valve to release any refrigerant (mine lightly hissed for

only a few seconds). Unless your refrigerant has leaked to the extent mine had, you

should have the system evacuated properly.

screwdriver and push in each valve to release any refrigerant (mine lightly hissed for

only a few seconds). Unless your refrigerant has leaked to the extent mine had, you

should have the system evacuated properly.

- Remove the shrader valve from the existing port (the shrader valve is the

pushpin valve). A pair of needle-nosed pliers may work, but a shrader

valve tool is probably necessary for the tight confines of the low side port.

- The quick-release valves screw on top of the valve ports.

Use teflon tape to help seal the fitting.

- The nuts on the receiver/drier are 19mm - mine were not tight. An oily

residue around any of the fittings may indicate a leak. When changing the o-rings

coat them with the new oil.

This is a squashed o-ring -

- Use a *good* allen wrench on the expansion valve to help avoid stripping

the bolt. Under the visible 5mm bolt are two smaller 3mm bolts for the rear brace.

The most difficulty is moving the

hard metal lines back enough to pull the expansion valve out.

One end at a time seemed to work.

The most difficulty is moving the

hard metal lines back enough to pull the expansion valve out.

One end at a time seemed to work.

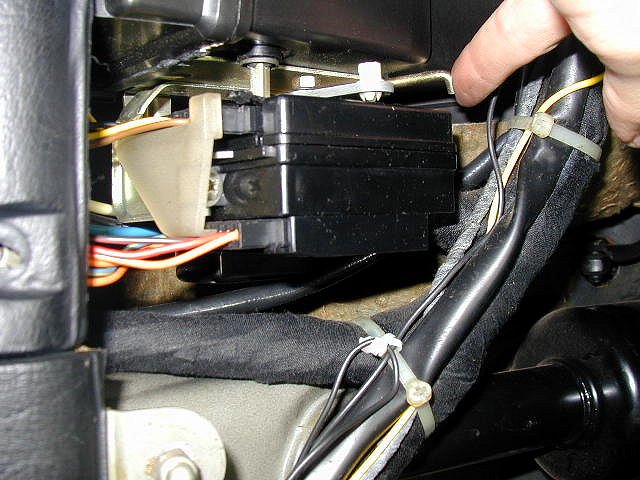

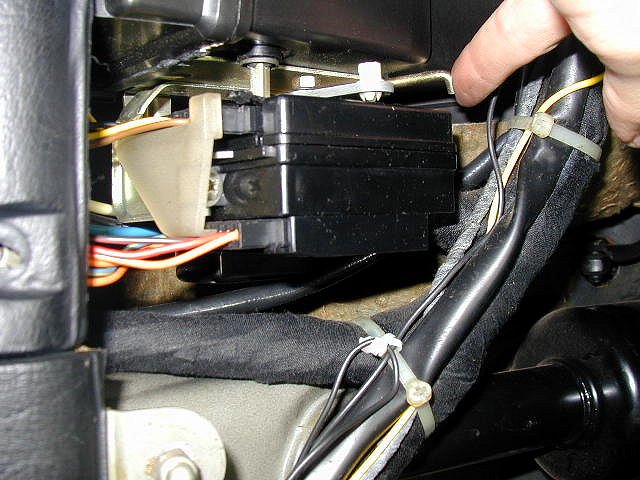

- Disconnect the a/c compressor electrical wire - usually found in front of the

right cam belt cover.

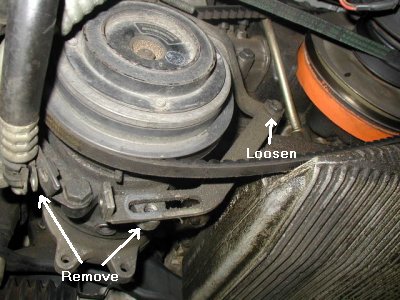

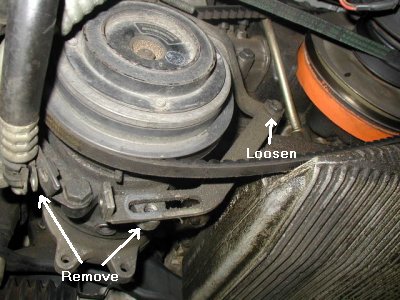

- Remove the two 10mm bolts holding the a/c hoses to the compressor.

Remove the a/c compressor belt tension bolts, and loosen the 13mm bolt

at the adjustment bracket pivot.

- The a/c compressor is mounted with two 17mm bolts at each end on top. A

stubby wrench helps on the front bolt.

Neither of these bolts needs to be completely removed - just withdrawn

sufficiently to permit the compressor to drop.

Neither of these bolts needs to be completely removed - just withdrawn

sufficiently to permit the compressor to drop.

- The hoses can only be removed with the compressor lowered, so support the

compressor carefully. I used some light hammer taps to get the nuts loosened - they

are large 27-28mm.

- Pull the compressor out, turn it over and empty the oil. Refill with 4 ounces

of the new oil.

- Change o-rings.

- Reconnect the lines.

- Bolt in the compressor.

- Tension the compressor belt.

- Reconnect the compressor electrical wire.

- Go have your system filled with R-134a.

From the manual page 87-01:

Refrigerant capacity is:

950 g

(The manual is not clear but this appears to be the capacity

for model years through 1983.)

From the manual page 87-90:

Refrigerant R12 volume up to July 1988 is:

1050 g

1200 g for cars with rear a/c

As of July 1988, the R12 volume is:

950 g

1150 g for cars with rear a/c

In converting from R12 to R134a, fill the system with 80% of the

amount specified for R12. So for a 1987 model with rear a/c:

1200 g x .80 = 960 g = 2.12 lb of R134a

There are many other o-rings in the system, especially if you have

rear a/c. Joel recommended servicing the parts in the hot engine compartment

that are most susceptible to decay and then dig into the interior later if

necessary. The rear a/c uses the same expansion valve, and there are also hose

fittings beneath the right seat.

Temperature mixer flaps

The flaps came from the factory with a foam seal around the edges. Over the

years the foam disintegrates leaving a gap which permits air to flow through

the heater core, warming up the a/c. These adjustments

should be made with the temp on maximum cold - the engine does not have to

be running but the ignition should be on.

- Looking up from the left footwell (driver side in US cars) there is

the electronic temperature mixer motor. Moving the temp slider switch from full cold

to full hot will cause the motor to raise and lower the link.

Disconnect the flap linkage arm from the motor.

- Pull the arm down as far as possible with the temp set to full cold.

If it pulls down further than the

connector at the motor then a gap is being left in the flaps. The top end

of the arm is a screw fitting, so turn the arm to adjust the length until it

matches with the motor, and reconnect. Some cars may have a locknut at

the top of the arm which will require removing the instrument pod.

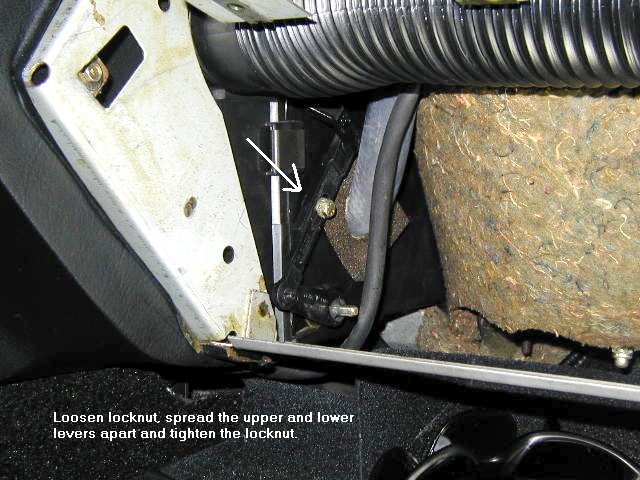

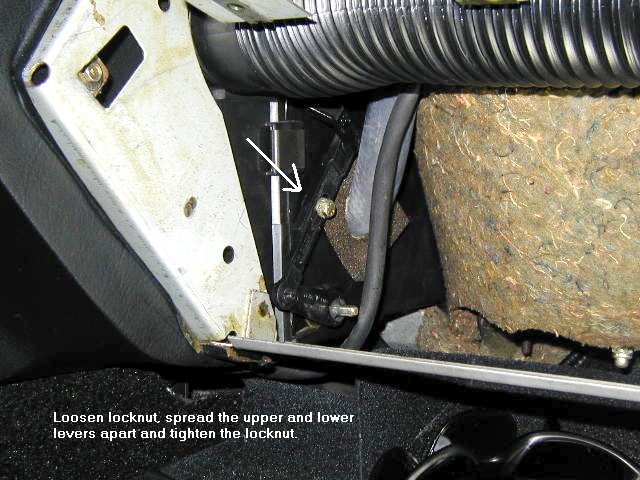

- The other mixer flap adjustment is on the right side of the HVAC housing. On US

cars the glovebox must be removed (see procedure for Interior - Center console). The

linkage on his side of the housing connects the upper flap to the lower flap so

that they both close off airflow to the heater core.

- Again, moving the temp slider switch from full cold to full hot will

move this flap linkage. The upper arm is connected to the same flap as the link at the

temp mixer motor - at full cold this arm will be at the bottom of it's travel.

Loosen the locknut connecting the two flap arms. With the temp full cold pull

the lower arm forward. This will spread the ends apart. Be sure to keep the linkage

at a "comfortable" fit. If the linkage is stretched too far apart a gap could be left

at the upper flap.

(Info on page 87-115 of the workshop manual.)

928 S4 Home

screwdriver and push in each valve to release any refrigerant (mine lightly hissed for

only a few seconds). Unless your refrigerant has leaked to the extent mine had, you

should have the system evacuated properly.

screwdriver and push in each valve to release any refrigerant (mine lightly hissed for

only a few seconds). Unless your refrigerant has leaked to the extent mine had, you

should have the system evacuated properly.

The most difficulty is moving the

hard metal lines back enough to pull the expansion valve out.

One end at a time seemed to work.

The most difficulty is moving the

hard metal lines back enough to pull the expansion valve out.

One end at a time seemed to work.

Neither of these bolts needs to be completely removed - just withdrawn

sufficiently to permit the compressor to drop.

Neither of these bolts needs to be completely removed - just withdrawn

sufficiently to permit the compressor to drop.