Once my 928 was back in my garage, drained the oil and filled it up with some 20w-50, still hoping that the sound might just be a sticky

hydraulic lifter. Unfortunately, the sound was still just as bad. A stethoscope revealed the sound was coming from the passenger side cylinder head,

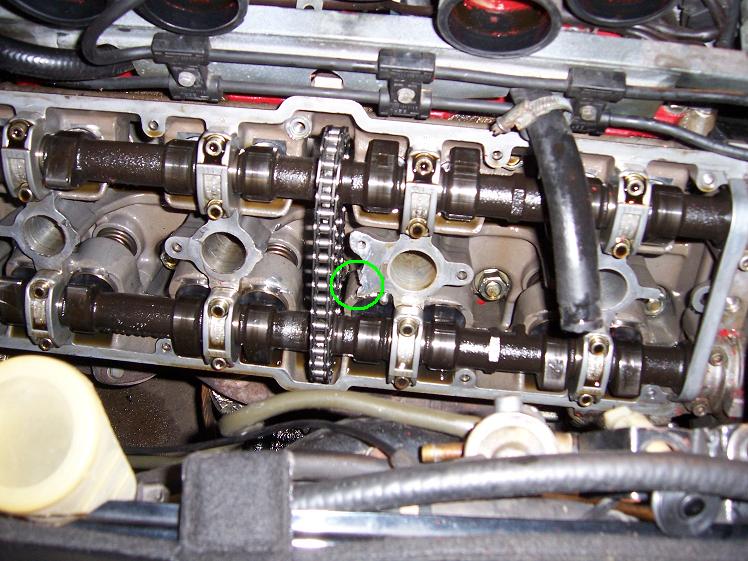

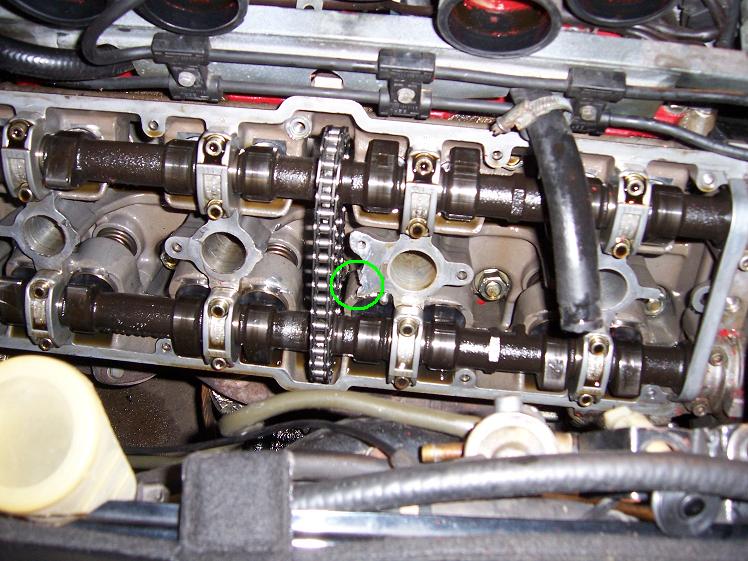

so it was time to remove the cam cover to take a look. With the cover off, I saw that the chain tensioner had actually broken free from the cylinder

head and was being hit by the moving chain and the teeth on the cams. 1 of the 2 mounting lobes on the cylinder head had broken clean off. Ugly.

Here's the chain tensioner. There was actually a lot of pad left on the tensioner, although it was badly chewed by the gear teeth.

Comparing my mangled chain tensioner to a normal tensioner:

I had to replace the cylinder head and go fishing for the debris that certainly had gone into the oil pan. Since the '85 engine uses head studs instead of head bolts,

I had to pull the engine AGAIN to be able to remove the cylinder head.

With the engine out, I was able to get a better look at the carnage. Notice the missing tooth on the cam gear. I was very lucky that the cams didn't skip some teeth

and destroy the valves (again).

There was a bunch of debris stuffed into the oil drain passage visible after I removed the head.

This is everything that was stuffed in the drain passage!

To give some perspective, this is a comparison of my broken head versus a normal one:

At this point the repair was easy. I just replaced the head, tensioner and cams using the knowledge I gained from my first rebuild (when my timing belt

failed). I also removed the oil pan to clean it out and replaced the oil filter. Then I buttoned everything back up.

A few friends came over to help drop the repaired engine back into the car. After a few days of hooking everything back up, I turned the key and it

started right up, nice and quiet again.

There was a bunch of debris stuffed into the oil drain passage visible after I removed the head.

This is everything that was stuffed in the drain passage!

To give some perspective, this is a comparison of my broken head versus a normal one:

At this point the repair was easy. I just replaced the head, tensioner and cams using the knowledge I gained from my first rebuild (when my timing belt failed). I also removed the oil pan to clean it out and replaced the oil filter. Then I buttoned everything back up.

A few friends came over to help drop the repaired engine back into the car. After a few days of hooking everything back up, I turned the key and it started right up, nice and quiet again.